Increased Military Spending

The US Aircraft Seals Market is poised to benefit from the rising military expenditure in the United States. The government has allocated substantial budgets for defense and aerospace projects, which include the procurement of advanced military aircraft. This increase in military spending is expected to drive demand for high-performance seals that ensure the integrity and reliability of military aircraft systems. The US Department of Defense has outlined plans to invest over $700 billion in defense for the fiscal year 2026, which includes modernization efforts for existing aircraft fleets. As a result, manufacturers in the US Aircraft Seals Market are likely to see heightened demand for seals that meet stringent military specifications and performance standards.

Focus on Regulatory Compliance

The US Aircraft Seals Market is heavily influenced by the focus on regulatory compliance and safety standards. The Federal Aviation Administration (FAA) and other regulatory bodies impose stringent requirements on aircraft components, including seals, to ensure safety and reliability. Compliance with these regulations is essential for manufacturers to maintain market access and avoid penalties. As the aviation industry evolves, regulations are becoming more rigorous, particularly concerning environmental impact and safety performance. This focus on compliance drives innovation in the design and manufacturing of seals, as companies strive to meet or exceed regulatory standards. Consequently, the US Aircraft Seals Market is likely to experience growth as manufacturers adapt to these changing requirements.

Expansion of Commercial Aviation

The US Aircraft Seals Market is witnessing growth due to the expansion of commercial aviation. As air travel continues to rebound, airlines are investing in fleet upgrades and new aircraft acquisitions to meet increasing passenger demand. This expansion necessitates the use of high-quality seals that ensure safety and efficiency in aircraft operations. The Federal Aviation Administration (FAA) has reported a steady increase in passenger numbers, projecting a rise to over 1 billion by 2028. This surge in commercial aviation activity is likely to create opportunities for seal manufacturers to provide innovative sealing solutions that enhance aircraft performance and reliability, thereby driving growth in the US Aircraft Seals Market.

Growing Demand for Lightweight Aircraft

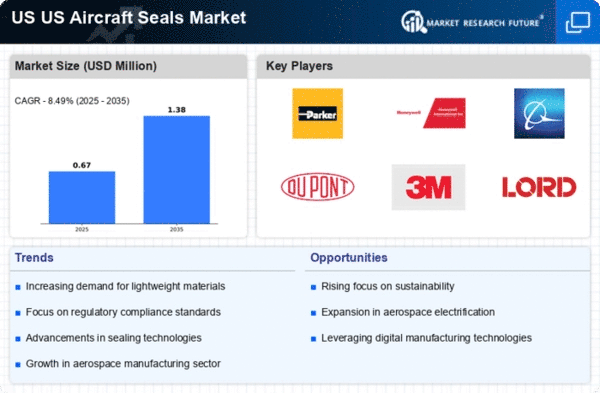

The US Aircraft Seals Market is experiencing a notable increase in demand for lightweight aircraft. This trend is driven by the aviation sector's focus on enhancing fuel efficiency and reducing operational costs. Lightweight materials, including advanced composites and polymers, are increasingly utilized in aircraft manufacturing. Consequently, the need for specialized seals that can withstand extreme conditions while maintaining low weight is paramount. According to industry reports, the lightweight aircraft segment is projected to grow at a compound annual growth rate (CAGR) of approximately 5% over the next five years. This growth is likely to propel the demand for innovative sealing solutions that cater to the unique requirements of lightweight aircraft, thereby shaping the US Aircraft Seals Market significantly.

Technological Innovations in Sealing Solutions

The US Aircraft Seals Market is significantly influenced by technological innovations in sealing solutions. Advances in materials science and engineering have led to the development of seals that offer superior performance, durability, and resistance to extreme environmental conditions. Innovations such as self-healing materials and advanced elastomers are becoming increasingly prevalent in the aerospace sector. These technologies not only improve the longevity of seals but also reduce maintenance costs for aircraft operators. As manufacturers continue to invest in research and development, the US Aircraft Seals Market is likely to see a surge in demand for these cutting-edge sealing solutions, which can enhance overall aircraft performance and safety.