Cost Reduction in Battery Manufacturing

Cost efficiency is a crucial factor driving the 3d printed-battery market. Traditional battery manufacturing processes often involve high material waste and labor costs. In contrast, 3D printing offers a more streamlined approach, allowing for the precise deposition of materials, which minimizes waste and reduces production costs. Reports indicate that companies utilizing 3D printing for battery production can achieve cost savings of up to 40% compared to conventional methods. This reduction in manufacturing costs is particularly appealing to startups and established companies alike, as it enables them to invest more in research and development. As the 3d printed-battery market continues to expand, the ability to produce batteries at a lower cost will likely attract more players to the industry, fostering innovation and competition.

Integration with Renewable Energy Sources

The integration of 3D printed batteries with renewable energy sources is emerging as a significant driver for the market. As the push for sustainable energy solutions intensifies, the demand for efficient energy storage systems becomes paramount. 3D printed batteries can be tailored to meet the specific requirements of solar and wind energy systems, providing a flexible and efficient storage solution. The ability to customize battery designs for optimal performance in renewable applications is a key advantage of 3D printing technology. Market forecasts suggest that the synergy between renewable energy and 3D printed batteries could lead to a 20% increase in market penetration by 2027. This trend highlights the potential for 3D printed batteries to play a crucial role in the transition to a more sustainable energy landscape.

Technological Advancements in 3D Printing

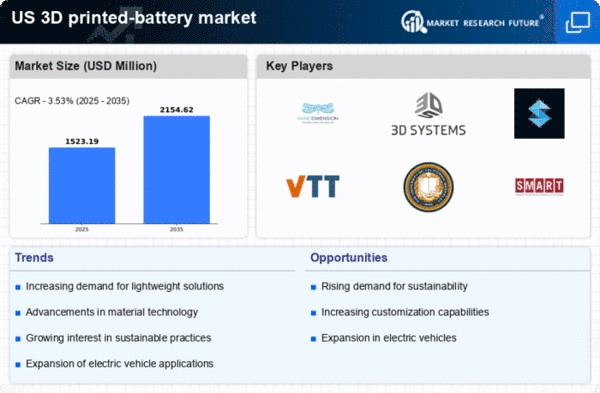

The rapid evolution of 3D printing technologies is a pivotal driver for the 3d printed-battery market. Innovations in materials and printing techniques enhance the efficiency and performance of batteries. For instance, advancements in conductive inks and polymer composites allow for the production of batteries with improved energy density and faster charging capabilities. The market is projected to grow at a CAGR of approximately 25% over the next five years, driven by these technological improvements. As manufacturers adopt more sophisticated 3D printing methods, the ability to create complex battery geometries becomes feasible, which could lead to lighter and more compact designs. This trend not only meets the increasing demand for portable energy solutions but also aligns with the customization needs of various industries, thereby propelling the growth of the 3d printed-battery market.

Growing Investment in Research and Development

Investment in research and development (R&D) is a vital driver for the 3d printed-battery market. As companies recognize the potential of 3D printing technology in battery production, funding for innovative projects is on the rise. Government initiatives and private sector investments are increasingly directed towards exploring new materials and processes that enhance battery performance. For instance, recent funding allocations have focused on developing solid-state batteries through 3D printing, which could revolutionize energy storage. Analysts predict that R&D investments in this sector could double by 2030, significantly impacting the growth trajectory of the 3d printed-battery market. This influx of capital not only accelerates technological advancements but also fosters collaboration between academia and industry, further driving innovation.

Rising Demand for Lightweight Energy Solutions

The increasing need for lightweight energy storage solutions is significantly influencing the 3d printed-battery market. Industries such as aerospace, automotive, and consumer electronics are actively seeking batteries that reduce overall weight without compromising performance. For example, the automotive sector is focusing on electric vehicles (EVs) that require lightweight batteries to enhance efficiency and range. The 3d printed-battery market is well-positioned to meet this demand, as 3D printing allows for the creation of intricate designs that can minimize weight while maximizing energy output. Market analysts estimate that the demand for lightweight batteries could lead to a 30% increase in market size by 2030, as manufacturers increasingly turn to 3D printing to achieve these objectives. This trend underscores the potential of 3D printing to revolutionize battery design and production.