Increased Focus on Sustainability

The automated optical inspection system market is also being driven by an increased focus on sustainability. As environmental regulations become more stringent, manufacturers are seeking ways to reduce waste and improve resource efficiency. Automated optical inspection systems contribute to sustainability by ensuring that only high-quality products proceed through the production line, thereby reducing scrap rates. In the UK, the push towards sustainable manufacturing practices is expected to grow, with a projected increase in investments in green technologies. This trend suggests that the automated optical-inspection-system market will benefit from the alignment of quality control with sustainability goals.

Expansion of the Electronics Sector

The expansion of the electronics sector is a significant driver for the automated optical-inspection-system market. With the increasing complexity of electronic components, the need for precise inspection systems has never been greater. The UK electronics industry is projected to grow by 6% annually, creating a robust demand for advanced inspection technologies. Automated optical inspection systems are essential for ensuring the reliability and performance of electronic devices, which are becoming more intricate. This growth in the electronics sector indicates a promising future for the automated optical-inspection-system market, as manufacturers seek to adopt cutting-edge solutions to meet evolving industry standards.

Rising Demand for Quality Assurance

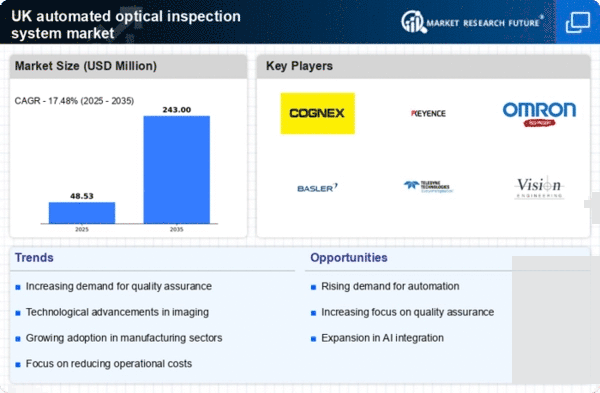

Quality assurance remains a pivotal driver in the automated optical-inspection-system market. With increasing competition, manufacturers in the UK are compelled to ensure that their products meet stringent quality standards. The adoption of automated inspection systems helps in achieving consistent quality, thereby reducing the risk of recalls and enhancing customer satisfaction. In 2025, it is estimated that the market for quality assurance technologies will reach £1.2 billion, reflecting a growing recognition of the importance of quality in manufacturing processes. This trend indicates that companies are investing in automated optical inspection systems to maintain their competitive edge.

Cost Reduction and Efficiency Improvement

Cost reduction and efficiency improvement are critical factors influencing the automated optical-inspection-system market. By implementing these systems, manufacturers can significantly lower operational costs associated with manual inspections. The automation of inspection processes not only speeds up production but also minimizes human error, leading to fewer defects and waste. In the UK, companies are increasingly recognizing that investing in automated optical inspection can yield a return on investment within 18 months, making it an attractive option. This focus on cost efficiency is likely to drive further adoption of automated optical-inspection systems across various industries.

Technological Advancements in Imaging Systems

The automated optical inspection system market is experiencing a surge due to rapid technological advancements in imaging systems. Innovations in high-resolution cameras and advanced lighting techniques enhance the accuracy and speed of inspections. For instance, the integration of 3D imaging and multispectral analysis allows for more detailed inspections, which is crucial in sectors like electronics and automotive manufacturing. The UK market is projected to grow at a CAGR of 8.5% from 2025 to 2030, driven by these technological improvements. As manufacturers seek to improve product quality and reduce defects, the demand for sophisticated optical inspection systems is likely to increase, thereby propelling the market forward.