Technological Advancements

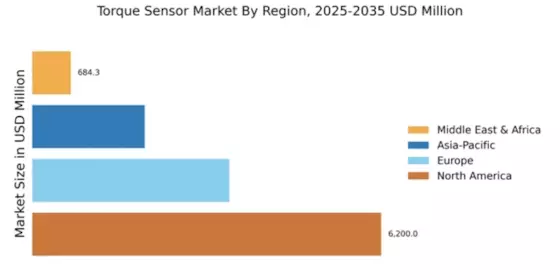

Technological advancements in sensor technology are driving the Global Torque Sensor Market Industry forward. Innovations such as wireless torque sensors and advanced data analytics capabilities enhance the functionality and application of torque sensors across various industries. These advancements enable real-time monitoring and data collection, facilitating better decision-making and operational efficiency. As industries increasingly rely on data-driven insights, the demand for sophisticated torque sensors is likely to grow. This trend may contribute to a compound annual growth rate (CAGR) of 6.5% from 2025 to 2035, indicating a robust future for the market.

Growth of Electric Vehicles

The Global Torque Sensor Market Industry is significantly influenced by the rapid growth of electric vehicles (EVs). As the automotive industry shifts towards electrification, the demand for torque sensors in EVs is expected to rise. These sensors are essential for monitoring the performance of electric motors and ensuring efficient power delivery. The increasing adoption of EVs, supported by government incentives and consumer preferences for sustainable transportation, is likely to contribute to the market's expansion. By 2035, the market could potentially reach 5000 USD Million, reflecting the critical role of torque sensors in the evolving automotive landscape.

Rising Demand for Automation

The Global Torque Sensor Market Industry experiences a surge in demand driven by the increasing automation across various sectors. Industries such as automotive, aerospace, and manufacturing are increasingly adopting automated systems to enhance efficiency and precision. This trend is expected to propel the market, as torque sensors play a crucial role in monitoring and controlling torque in automated machinery. With the market projected to reach 2500 USD Million in 2024, the integration of torque sensors in automated processes is likely to be a key driver of growth, ensuring optimal performance and safety in operations.

Expansion in Industrial Applications

The Global Torque Sensor Market Industry is witnessing expansion due to the growing applications of torque sensors in various industrial sectors. Industries such as oil and gas, aerospace, and manufacturing are increasingly utilizing torque sensors for monitoring and controlling torque in critical operations. This diversification of applications is likely to drive market growth, as companies seek to enhance operational efficiency and reduce downtime. The integration of torque sensors in diverse industrial processes may contribute to the overall market growth, aligning with the projected increase in market value to 2500 USD Million by 2024.

Increasing Focus on Safety Standards

The Global Torque Sensor Market Industry is also propelled by the increasing focus on safety standards across industries. Regulatory bodies are implementing stringent safety regulations that necessitate the use of torque sensors in machinery and equipment. These sensors help ensure that torque levels remain within safe limits, thereby preventing equipment failures and accidents. As industries prioritize safety and compliance, the demand for torque sensors is expected to rise. This trend aligns with the broader movement towards enhancing workplace safety and operational reliability, further solidifying the market's growth trajectory.