Regulatory Compliance

Regulatory compliance is a significant driver in the Technical Coil Coating Market. Governments worldwide are implementing stringent regulations regarding emissions and environmental impact, compelling manufacturers to adapt their processes and products accordingly. Compliance with these regulations often necessitates the development of low-VOC and non-toxic coatings, which can lead to increased production costs. However, companies that successfully navigate these regulatory landscapes may benefit from enhanced market access and consumer trust. The Technical Coil Coating Market is likely to see a shift towards compliant products, with market data indicating that adherence to regulations could influence purchasing decisions for up to 70% of consumers in certain regions.

Sustainability Initiatives

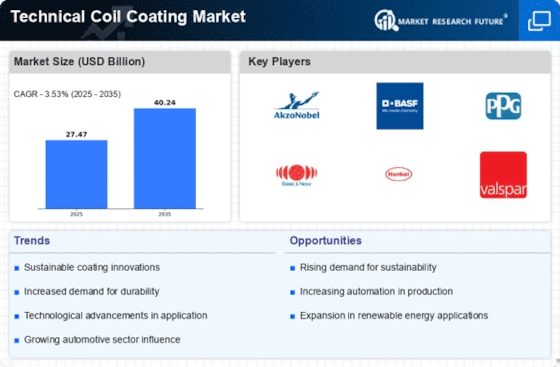

The Technical Coil Coating Market is increasingly influenced by sustainability initiatives. Manufacturers are adopting eco-friendly practices, such as using water-based coatings and reducing volatile organic compounds (VOCs). This shift not only meets regulatory requirements but also appeals to environmentally conscious consumers. The market for sustainable coil coatings is projected to grow, with estimates suggesting a compound annual growth rate (CAGR) of around 5% over the next five years. Companies that prioritize sustainability may gain a competitive edge, as they align with the growing demand for green products. Furthermore, the emphasis on recycling and reusability in the Technical Coil Coating Market is likely to enhance the lifecycle of coated products, thereby reducing waste and promoting a circular economy.

Technological Advancements

Technological advancements play a pivotal role in shaping the Technical Coil Coating Market. Innovations in coating formulations and application techniques have led to improved performance characteristics, such as enhanced durability and corrosion resistance. The introduction of advanced curing technologies, including ultraviolet (UV) and electron beam (EB) curing, has revolutionized the coating process, allowing for faster production times and lower energy consumption. Market data indicates that the adoption of these technologies could potentially increase efficiency by up to 30%. As manufacturers continue to invest in research and development, the Technical Coil Coating Market is expected to witness a surge in high-performance coatings that cater to diverse applications, from construction to automotive.

Growing Construction Sector

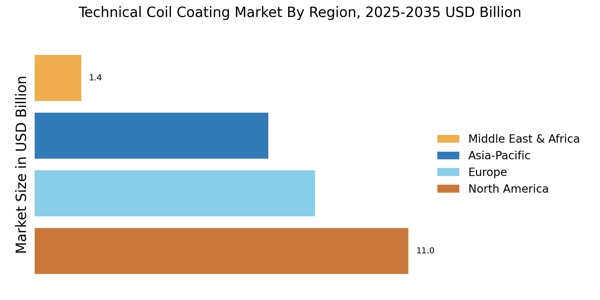

The growing construction sector is a key driver of the Technical Coil Coating Market. As urbanization accelerates and infrastructure projects expand, the demand for coated materials in construction applications is on the rise. Coated steel and aluminum are increasingly favored for their aesthetic appeal and protective qualities. Market forecasts suggest that the construction industry will experience a growth rate of approximately 4% annually, which will, in turn, bolster the demand for technical coil coatings. This trend is particularly pronounced in emerging markets, where rapid urban development is creating new opportunities for manufacturers in the Technical Coil Coating Market.

Customization and Versatility

Customization and versatility are becoming increasingly vital in the Technical Coil Coating Market. As end-users demand tailored solutions to meet specific aesthetic and functional requirements, manufacturers are responding by offering a wider range of colors, finishes, and textures. This trend is particularly evident in sectors such as architecture and interior design, where unique coatings can enhance the visual appeal of buildings and products. Market analysis suggests that the customization segment is likely to grow at a CAGR of approximately 6% over the next few years. The ability to provide bespoke solutions not only satisfies customer preferences but also positions companies favorably within the competitive landscape of the Technical Coil Coating Market.