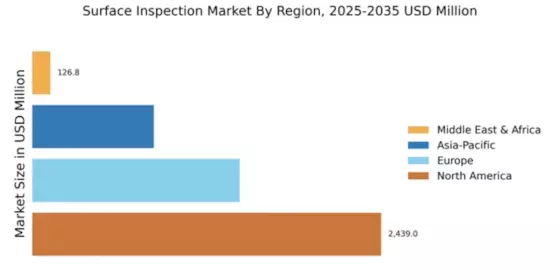

North America : Market Leader in Innovation

North America continues to lead the Surface Inspection Market, holding a significant share of 2439.0 million, driven by strong adoption of automated surface inspection systems. The region's growth is driven by advancements in automation, increasing demand for quality assurance, and stringent regulatory standards. The presence of major players like Cognex Corporation and Teledyne Technologies further fuels market expansion, as they innovate and enhance product offerings to meet diverse industrial needs. The United States stands out as the primary market, supported by a robust manufacturing sector and a focus on technological integration. Companies are investing heavily in R&D to develop cutting-edge solutions, ensuring competitive advantage. The market is characterized by a mix of established firms and emerging startups, all vying for a share in this lucrative landscape. With a projected growth trajectory, North America is set to maintain its leadership position in the coming years.

Europe : Emerging Technologies and Standards

Europe's Surface Inspection Market is projected to reach €1450.0, driven by stringent regulations and a growing emphasis on quality assurance across various sectors. The region is witnessing a surge in demand for advanced inspection systems, particularly in automotive and aerospace industries, where compliance with safety standards is critical. Regulatory bodies are increasingly mandating the use of automated inspection technologies to enhance product quality and reduce defects. Leading countries such as Germany, France, and the UK are at the forefront of this market, hosting major players like Basler AG and SICK AG. The competitive landscape is characterized by a mix of established firms and innovative startups, all striving to meet the evolving demands of the market. The European market is also influenced by initiatives aimed at promoting Industry 4.0, further driving the adoption of smart inspection solutions.

Asia-Pacific : Rapid Growth and Adoption

The Asia-Pacific region is rapidly emerging as a significant player in the Surface Inspection Market, with a projected size of $850.0. The growth is primarily driven by the increasing industrialization and the rising demand for automation in manufacturing processes. Countries like China, Japan, and India are leading this trend, as they invest heavily in modernizing their manufacturing capabilities to enhance productivity and quality control. The competitive landscape is evolving, with both local and international players vying for market share. Key companies such as Keyence Corporation and Omron Corporation are expanding their presence in the region, offering innovative solutions tailored to local market needs. The focus on smart manufacturing and the integration of AI technologies are expected to further propel the growth of the surface inspection market in Asia-Pacific.

Middle East and Africa : Emerging Market with Potential

The Middle East and Africa region, with a market size of $126.84, presents emerging opportunities in the Surface Inspection Market. The growth is driven by increasing investments in infrastructure and manufacturing, particularly in countries like the UAE and South Africa. The demand for quality assurance in manufacturing processes is rising, spurred by the need for compliance with international standards and the growing focus on product quality. The competitive landscape is still developing, with a mix of local and international players entering the market. Companies are beginning to recognize the importance of advanced inspection technologies to enhance operational efficiency. As the region continues to industrialize, the adoption of surface inspection systems is expected to grow, providing significant opportunities for market players.