Increasing Demand in Electronics

The Specialty Methacrylate Market is benefiting from the increasing demand for specialty materials in the electronics sector. Specialty methacrylates are utilized in various electronic applications, including encapsulants, adhesives, and coatings, which are essential for ensuring the reliability and performance of electronic devices. As the electronics industry continues to evolve, driven by advancements in technology and consumer preferences, the demand for high-quality materials is expected to rise. Recent market analyses suggest that the electronics sector is projected to grow at a compound annual growth rate of approximately 6% over the next few years, which could significantly bolster the Specialty Methacrylate Market. This trend indicates a promising future for specialty methacrylates as they become integral to the development of next-generation electronic products.

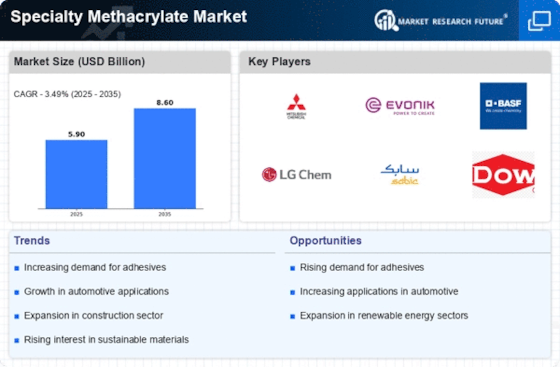

Rising Demand in Automotive Sector

The Specialty Methacrylate Market is experiencing a notable surge in demand from the automotive sector. This growth is primarily driven by the increasing need for lightweight materials that enhance fuel efficiency and reduce emissions. Specialty methacrylates are utilized in various automotive applications, including adhesives, coatings, and composites, which are essential for manufacturing durable and efficient vehicles. According to recent data, the automotive industry is projected to grow at a compound annual growth rate of approximately 4% over the next few years, further propelling the demand for specialty methacrylates. As manufacturers seek to innovate and comply with stringent environmental regulations, the Specialty Methacrylate Market is likely to benefit from this trend, positioning itself as a critical component in the evolution of automotive technologies.

Expansion in Construction Activities

The Specialty Methacrylate Market is poised for growth due to the expansion of construction activities across various regions. The construction sector increasingly adopts specialty methacrylates for applications such as sealants, adhesives, and coatings, which are vital for enhancing the durability and aesthetic appeal of structures. With urbanization and infrastructure development on the rise, the demand for high-performance materials is expected to increase. Recent statistics indicate that the construction industry is anticipated to grow at a rate of around 5% annually, which could significantly impact the Specialty Methacrylate Market. This growth is likely to be fueled by the need for sustainable building practices and the incorporation of advanced materials that offer superior performance and longevity.

Growth in Renewable Energy Applications

The Specialty Methacrylate Market is likely to experience growth due to the increasing adoption of renewable energy technologies. Specialty methacrylates are utilized in various applications within the renewable energy sector, including solar panel manufacturing and wind turbine production. As the world shifts towards sustainable energy solutions, the demand for high-performance materials that can withstand harsh environmental conditions is expected to rise. Recent reports indicate that the renewable energy market is projected to grow at a rate of around 8% annually, which could have a positive impact on the Specialty Methacrylate Market. This growth presents opportunities for manufacturers to innovate and develop specialized products that cater to the unique requirements of renewable energy applications.

Technological Innovations in Production

Technological advancements in the production of specialty methacrylates are driving the Specialty Methacrylate Market forward. Innovations such as improved polymerization techniques and the development of bio-based methacrylates are enhancing the efficiency and sustainability of production processes. These advancements not only reduce production costs but also align with the growing demand for environmentally friendly materials. As manufacturers invest in research and development, the Specialty Methacrylate Market is likely to witness an influx of new products that cater to diverse applications. The introduction of novel formulations and enhanced performance characteristics could potentially expand market opportunities, making it a dynamic sector within the broader chemical industry.