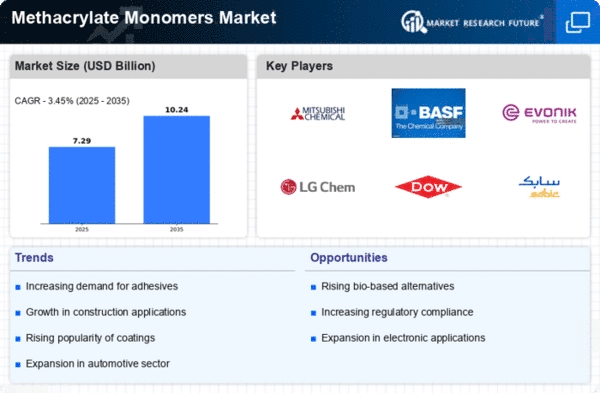

Market Trends and Projections

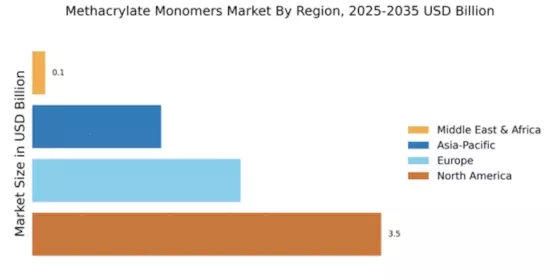

The Global Methacrylate Monomers Market Industry is characterized by various trends and projections that reflect its dynamic nature. The market is expected to grow steadily, with a projected value of 19.0 USD Billion in 2024 and an anticipated increase to 35.5 USD Billion by 2035. This growth trajectory indicates a compound annual growth rate of 5.82% from 2025 to 2035. Factors such as rising demand in automotive and construction sectors, technological advancements, and increasing applications in medical devices contribute to this positive outlook. These trends suggest a robust future for the methacrylate monomers market, driven by innovation and evolving consumer needs.

Growth in Construction Activities

The Global Methacrylate Monomers Market Industry is significantly influenced by the growth in construction activities worldwide. Methacrylate monomers are utilized in various applications, including adhesives, sealants, and coatings, which are essential in modern construction projects. As urbanization accelerates and infrastructure development intensifies, the demand for high-performance materials is expected to rise. This trend is particularly evident in emerging economies, where rapid urban development is underway. The market is anticipated to benefit from this growth, with projections indicating a market size of 35.5 USD Billion by 2035, reflecting the increasing reliance on methacrylate-based products in construction.

Rising Demand in Automotive Sector

The Global Methacrylate Monomers Market Industry experiences a notable surge in demand driven by the automotive sector. Methacrylate monomers are integral in the production of lightweight and durable materials, which are increasingly utilized in vehicle manufacturing. As automotive manufacturers strive to enhance fuel efficiency and reduce emissions, the adoption of methacrylate-based composites is likely to grow. This trend is projected to contribute to the market's expansion, with the industry expected to reach 19.0 USD Billion in 2024. The automotive industry's shift towards sustainable materials further underscores the importance of methacrylate monomers in meeting regulatory standards and consumer preferences.

Technological Advancements in Production

Technological advancements in the production of methacrylate monomers are poised to drive the Global Methacrylate Monomers Market Industry forward. Innovations in manufacturing processes, such as the development of more efficient catalysts and greener production methods, enhance yield and reduce environmental impact. These advancements not only improve the cost-effectiveness of methacrylate monomers but also align with global sustainability goals. As manufacturers adopt these technologies, the market is likely to witness increased competitiveness and growth. The anticipated compound annual growth rate of 5.82% from 2025 to 2035 indicates a robust future for the industry, fueled by these technological improvements.

Increasing Applications in Medical Devices

The Global Methacrylate Monomers Market Industry is experiencing growth due to the increasing applications of methacrylate monomers in medical devices. These monomers are crucial in the production of biocompatible materials used in various medical applications, including dental products, orthopedic devices, and drug delivery systems. As the healthcare sector continues to evolve, the demand for innovative and reliable materials is likely to rise. The ability of methacrylate monomers to provide strength and durability while maintaining biocompatibility positions them favorably in the medical market. This trend suggests a promising future for the industry as it adapts to the growing needs of healthcare.

Environmental Regulations and Sustainability Initiatives

The Global Methacrylate Monomers Market Industry is increasingly shaped by environmental regulations and sustainability initiatives. Governments worldwide are implementing stricter regulations aimed at reducing the environmental impact of chemical production. This has led to a shift towards more sustainable practices within the methacrylate industry, including the development of bio-based monomers and eco-friendly production methods. Companies that prioritize sustainability are likely to gain a competitive edge, as consumers and industries alike become more environmentally conscious. This shift not only aligns with global sustainability goals but also positions the methacrylate monomers market for growth in the coming years.