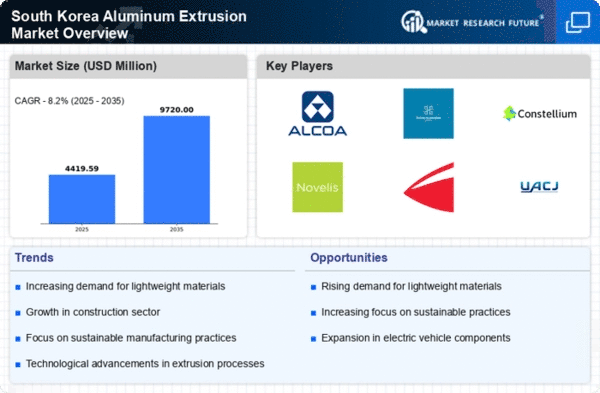

The aluminum extrusion market in South Korea is characterized by a competitive landscape that is increasingly shaped by innovation, sustainability, and strategic partnerships. Key players such as Alcoa Corporation (US), Novelis Inc. (US), and UACJ Corporation (JP) are actively pursuing strategies that emphasize technological advancement and operational efficiency. Alcoa Corporation (US) has focused on enhancing its production capabilities through investments in advanced manufacturing technologies, which positions it favorably in a market that demands high-quality and customized solutions. Meanwhile, Novelis Inc. (US) has been leveraging its expertise in recycling and sustainability to cater to the growing demand for eco-friendly products, thereby reinforcing its market presence. UACJ Corporation (JP) appears to be concentrating on regional expansion, particularly in Southeast Asia, which may enhance its competitive edge in the broader Asian market.The business tactics employed by these companies reflect a trend towards localizing manufacturing and optimizing supply chains to better serve regional markets. The competitive structure of the market is moderately fragmented, with several players vying for market share. However, the collective influence of major companies like Alcoa and Novelis suggests a potential for consolidation, as these firms seek to enhance their operational efficiencies and market reach.

In September Alcoa Corporation (US) announced a strategic partnership with a leading technology firm to develop AI-driven solutions for optimizing aluminum production processes. This move is likely to enhance Alcoa's operational efficiency and reduce production costs, thereby strengthening its competitive position in the market. The integration of AI technology may also lead to improved product quality and faster response times to customer demands.

In October Novelis Inc. (US) unveiled a new initiative aimed at increasing its recycling capacity by 30% over the next two years. This initiative underscores Novelis's commitment to sustainability and positions the company to meet the rising demand for recycled aluminum products. By enhancing its recycling capabilities, Novelis not only addresses environmental concerns but also secures a more stable supply chain, which is crucial in a market where raw material prices can be volatile.

In August UACJ Corporation (JP) expanded its production facility in South Korea, aiming to increase its output by 20% within the next year. This expansion is indicative of UACJ's strategy to capitalize on the growing demand for aluminum extrusions in various sectors, including automotive and construction. By boosting its production capacity, UACJ is likely to enhance its market share and improve its competitive stance against other key players.

As of November the competitive trends in the aluminum extrusion market are increasingly defined by digitalization, sustainability, and the integration of advanced technologies. Strategic alliances are becoming more prevalent, as companies recognize the need to collaborate in order to innovate and meet evolving market demands. The shift from price-based competition to a focus on innovation, technology, and supply chain reliability is evident, suggesting that future competitive differentiation will hinge on these factors. Companies that can effectively leverage technology and sustainability in their operations are likely to emerge as leaders in this dynamic market.