Expansion of End-User Industries

The expansion of end-user industries is significantly contributing to the growth of the Separation Machinery Market. Sectors such as chemicals, pharmaceuticals, and food processing are increasingly relying on advanced separation technologies to enhance their production processes. The rising demand for high-purity products and the need for efficient waste management are driving investments in separation machinery. Additionally, the growth of the renewable energy sector is creating new opportunities for separation technologies, particularly in biofuels and waste-to-energy applications. This diversification across various industries is likely to sustain the momentum of the Separation Machinery Market in the coming years.

Growing Focus on Environmental Sustainability

The growing focus on environmental sustainability is a key driver for the Separation Machinery Market. Companies are increasingly adopting separation technologies that minimize environmental impact and promote resource recovery. This shift is largely influenced by consumer preferences for sustainable products and the need to adhere to environmental regulations. The market is witnessing a rise in the development of eco-friendly separation solutions, which not only meet regulatory requirements but also enhance brand reputation. As organizations strive to achieve sustainability goals, the demand for innovative separation machinery is expected to increase, thereby propelling the growth of the Separation Machinery Market.

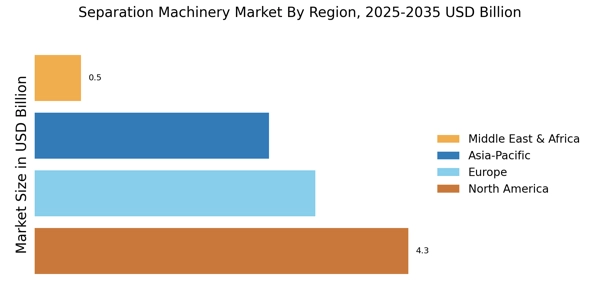

Increasing Industrialization and Urbanization

The ongoing trends of industrialization and urbanization are significantly influencing the Separation Machinery Market. As more industries emerge and urban areas expand, the demand for separation machinery is likely to rise. This is particularly evident in sectors such as food and beverage, pharmaceuticals, and wastewater treatment, where efficient separation processes are crucial. The market is projected to benefit from the increasing need for high-quality products and effective waste management solutions. Furthermore, the expansion of manufacturing facilities in developing regions is expected to create new opportunities for the Separation Machinery Market, potentially leading to a robust growth trajectory.

Rising Demand for Efficient Resource Management

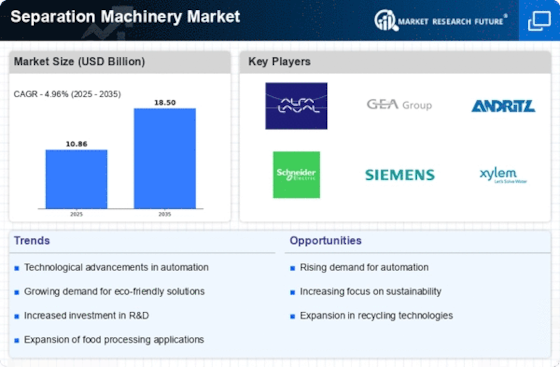

The Separation Machinery Market is experiencing a notable increase in demand for efficient resource management solutions. Industries are increasingly focusing on optimizing their processes to reduce waste and enhance productivity. This trend is driven by the need to comply with stringent environmental regulations and the growing emphasis on sustainability. For instance, the market for separation machinery is projected to grow at a compound annual growth rate of approximately 5.2% over the next five years. Companies are investing in advanced separation technologies to improve their operational efficiency, which in turn is propelling the growth of the Separation Machinery Market.

Technological Advancements in Separation Processes

Technological advancements are playing a pivotal role in shaping the Separation Machinery Market. Innovations such as membrane separation, centrifugation, and advanced filtration techniques are enhancing the efficiency and effectiveness of separation processes. These technologies not only improve the quality of the end products but also reduce energy consumption and operational costs. The integration of smart technologies, such as IoT and AI, is further optimizing separation processes, allowing for real-time monitoring and adjustments. As a result, the market is witnessing a surge in the adoption of these advanced separation technologies, which is expected to drive growth in the Separation Machinery Market.