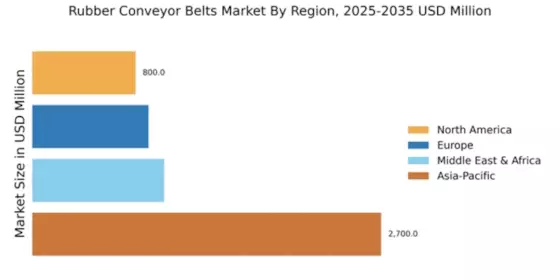

Market Growth Projections

The Rubber Conveyor Belt Industry is poised for substantial growth, with projections indicating a market valuation of 6.56 USD Billion by 2035. This growth trajectory suggests a compound annual growth rate (CAGR) of 3.86% from 2025 to 2035. Such figures reflect the increasing adoption of conveyor systems across various sectors, driven by technological advancements and rising demand for efficient material handling solutions. The market's expansion is likely to be influenced by factors such as industrial automation, sustainability initiatives, and the ongoing evolution of supply chain dynamics.

Growth in E-Commerce and Logistics

The surge in e-commerce and logistics activities is significantly impacting the Rubber Conveyor Belts Market. With the increasing volume of goods being transported, efficient material handling systems are essential for warehouses and distribution centers. Conveyor belts play a crucial role in streamlining operations, reducing labor costs, and improving order fulfillment times. This trend is expected to contribute to the market's growth, with projections indicating a valuation of 6.56 USD Billion by 2035. The logistics sector's reliance on advanced conveyor systems underscores the importance of rubber conveyor belts in modern supply chain management.

Expansion of Manufacturing Industries

The expansion of manufacturing industries globally is a key driver of the Rubber Belt Conveyor Market. As production processes become more complex, the need for reliable and efficient material handling solutions increases. Conveyor belts are integral to various manufacturing operations, facilitating the movement of raw materials and finished products. This growth is reflected in the anticipated market valuation of 4.32 USD Billion by 2024. The continuous investment in manufacturing capabilities across different regions further emphasizes the critical role of rubber conveyor belts in enhancing operational efficiency.

Technological Advancements in Conveyor Systems

Technological innovations in conveyor systems are propelling the Rubber Belt Conveyor Market forward. The integration of smart technologies, such as IoT and automation, enhances the efficiency and reliability of overhead conveyor systems. These advancements allow for real-time monitoring and predictive maintenance, reducing downtime and increasing operational efficiency. Companies are increasingly adopting these technologies to optimize their supply chains. As a result, the market is expected to grow at a CAGR of 3.86% from 2025 to 2035, reflecting the industry's shift towards more sophisticated and automated solutions.

Rising Demand in Mining and Construction Sectors

The Industrial Conveyor Belts Market experiences a robust demand driven by the mining and construction sectors. As these industries expand, the need for efficient material handling solutions becomes paramount. Conveyor belts facilitate the transportation of heavy materials, enhancing productivity and reducing operational costs. For instance, the mining sector's growth is projected to contribute significantly to the market, with an expected valuation of 4.32 USD Billion by 2024. This trend indicates a strong reliance on rubber conveyor belts, which are essential for the seamless movement of materials in challenging environments.

Sustainability Initiatives and Eco-Friendly Materials

Sustainability initiatives are becoming increasingly influential in the Rubber Transport Belts Market. Manufacturers are exploring eco-friendly materials and production processes to meet the growing demand for sustainable solutions. The shift towards recyclable and biodegradable materials not only addresses environmental concerns but also aligns with regulatory requirements. Companies that adopt these practices may gain a competitive edge in the market. As the industry evolves, the focus on sustainability is likely to shape product development and consumer preferences, further driving market growth.