Rising Demand for Tires

The Rubber Chemical Market is experiencing a notable increase in demand for tires, driven by the automotive sector's growth. As vehicle production rises, the need for high-performance tires that offer durability and safety becomes paramount. In 2025, the tire segment is projected to account for a substantial share of the rubber chemicals market, with estimates suggesting a value exceeding USD 20 billion. This demand is further fueled by the growing trend towards electric vehicles, which require specialized rubber compounds to enhance performance and efficiency. Consequently, manufacturers are investing in advanced rubber chemicals to meet these evolving requirements, indicating a robust growth trajectory for the Rubber Chemical Market.

Growing Environmental Regulations

The Rubber Chemical Market is increasingly shaped by growing environmental regulations aimed at reducing the ecological footprint of manufacturing processes. Stricter regulations on emissions and waste management are compelling rubber chemical manufacturers to adopt sustainable practices. In 2025, it is estimated that the market for eco-friendly rubber chemicals will grow by 10%, driven by the demand for greener alternatives. This shift not only aligns with regulatory requirements but also meets consumer preferences for sustainable products. As a result, companies are investing in research and development to create biodegradable and non-toxic rubber chemicals, which could potentially transform the landscape of the Rubber Chemical Market.

Emerging Markets and Economic Growth

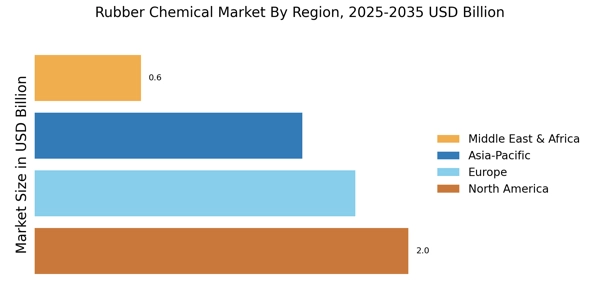

Emerging markets are playing a pivotal role in the growth of the Rubber Chemical Market. Countries in Asia and Latin America are witnessing rapid economic development, leading to increased industrialization and urbanization. This economic growth is driving demand for rubber products across various sectors, including automotive, construction, and consumer goods. In 2025, it is projected that these emerging markets will account for over 40% of the total rubber chemicals consumption. The rising middle class in these regions is also contributing to higher disposable incomes, which in turn fuels demand for quality rubber products. This trend suggests a favorable outlook for the Rubber Chemical Market as it adapts to the needs of these burgeoning economies.

Expansion of Construction Activities

The Rubber Chemical Market is significantly influenced by the expansion of construction activities worldwide. As urbanization accelerates, the demand for construction materials, including rubber-based products, is on the rise. In 2025, the construction sector is expected to contribute approximately 30% to the overall rubber chemicals market. This growth is attributed to the increasing use of rubber in various applications such as flooring, roofing, and insulation materials. Additionally, the emphasis on sustainable building practices is prompting manufacturers to develop eco-friendly rubber chemicals, further enhancing their market presence. The synergy between construction growth and rubber chemical innovations suggests a promising outlook for the Rubber Chemical Market.

Technological Innovations in Rubber Processing

Technological innovations in rubber processing are reshaping the Rubber Chemical Market. Advanced processing techniques, such as the use of nanotechnology and automation, are enhancing the efficiency and quality of rubber products. These innovations enable manufacturers to produce specialized rubber chemicals that cater to diverse applications, including automotive, aerospace, and consumer goods. In 2025, the market for rubber processing chemicals is anticipated to reach USD 15 billion, reflecting a compound annual growth rate of 5%. This growth is indicative of the industry's shift towards high-performance materials that meet stringent regulatory standards. As manufacturers adopt these technologies, the Rubber Chemical Market is likely to witness increased competitiveness and product differentiation.