Expansion of End-Use Industries

The expansion of various end-use industries, including personal care, food and beverage, and pharmaceuticals, is driving the demand for rheology modifiers. These industries require rheology modifiers to enhance product texture, stability, and performance. The Global Rheology Modifiers Industry is benefiting from this diversification, as manufacturers adapt their offerings to cater to the specific needs of these sectors. In 2023, the personal care industry accounted for approximately 20% of the total market share, highlighting the importance of rheology modifiers in formulating creams, lotions, and other cosmetic products. This trend is expected to continue, as the demand for high-quality, performance-driven products in these industries grows, thereby supporting the overall expansion of the market.

Growth in Automotive Applications

The automotive industry is witnessing a significant transformation, with rheology modifiers playing a crucial role in enhancing the performance of various automotive products. These modifiers are utilized in coatings, sealants, and adhesives, contributing to improved durability and aesthetic appeal. The Global Rheology Modifiers Industry is poised to capitalize on this growth, as the automotive sector increasingly adopts advanced materials to meet stringent regulatory standards and consumer expectations. In 2023, automotive applications represented around 25% of the overall market share for rheology modifiers. This trend is expected to persist, driven by the rising demand for lightweight and high-performance vehicles, which necessitate the use of innovative materials that incorporate rheology modifiers.

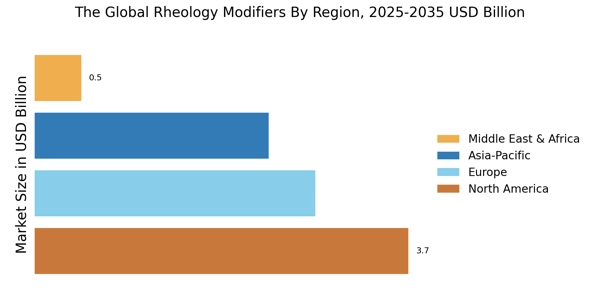

Rising Demand in Construction Sector

The construction sector is experiencing a notable surge in demand for rheology modifiers, driven by the need for high-performance materials. These modifiers enhance the viscosity and stability of construction materials, such as paints, coatings, and adhesives. As infrastructure projects expand, The Global Rheology Modifiers Industry is likely to benefit from this trend. In 2023, the construction industry accounted for approximately 30% of the total demand for rheology modifiers, indicating a robust growth trajectory. This demand is expected to continue, as construction companies increasingly prioritize the use of advanced materials to improve durability and performance. Furthermore, the integration of rheology modifiers in construction applications is anticipated to enhance product quality, thereby fostering greater market penetration and expansion.

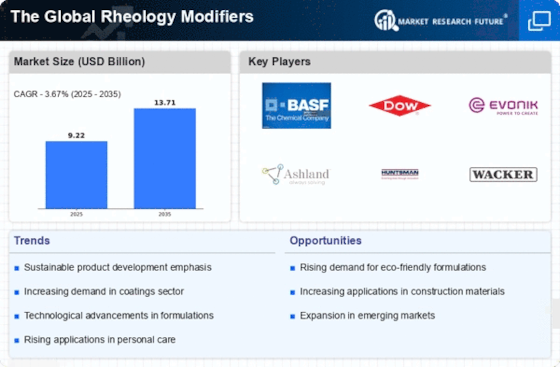

Increasing Focus on Sustainable Products

The growing emphasis on sustainability is reshaping The Global Rheology Modifiers Industry. Consumers and manufacturers alike are increasingly seeking eco-friendly alternatives that minimize environmental impact. Rheology modifiers derived from renewable resources are gaining traction, as they align with the global shift towards sustainable practices. In 2023, the market for bio-based rheology modifiers grew by approximately 15%, reflecting a broader trend towards sustainability in various industries. This shift is likely to encourage manufacturers to innovate and develop products that not only meet performance standards but also adhere to environmental regulations. As sustainability becomes a key purchasing criterion, the demand for eco-friendly rheology modifiers is expected to rise, further propelling market growth.

Technological Advancements in Manufacturing

Technological advancements in manufacturing processes are significantly influencing The Global Rheology Modifiers Industry. Innovations in production techniques, such as the development of new polymer blends and formulations, are enhancing the performance characteristics of rheology modifiers. These advancements enable manufacturers to create products that meet specific application requirements, thereby expanding their market reach. In recent years, the introduction of smart manufacturing technologies has streamlined production, resulting in increased efficiency and reduced costs. This trend is likely to continue, as companies invest in research and development to create more effective and sustainable rheology modifiers. The ability to customize products based on end-user needs is expected to drive further growth in the market.