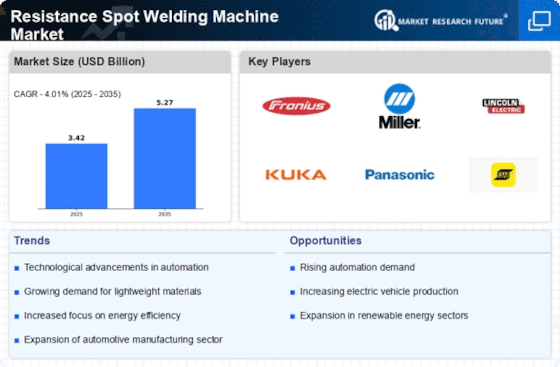

Rising Automotive Production

The increasing production of automobiles is a primary driver for the Resistance Spot Welding Machine Market. As manufacturers strive to enhance vehicle quality and reduce production costs, the demand for efficient welding solutions rises. In 2025, the automotive sector is projected to account for a substantial share of the market, with estimates suggesting that nearly 60% of resistance spot welding machines are utilized in automotive applications. This trend is likely to continue as automakers increasingly adopt advanced welding technologies to meet stringent safety and performance standards. Furthermore, the shift towards electric vehicles may further bolster the demand for these machines, as new models often require innovative welding techniques to ensure structural integrity and performance.

Increased Focus on Automation

The growing emphasis on automation in manufacturing processes is a significant driver for the Resistance Spot Welding Machine Market. As industries seek to enhance productivity and reduce labor costs, the integration of automated welding solutions becomes increasingly prevalent. In 2025, it is expected that a considerable portion of resistance spot welding machines will be incorporated into automated systems, allowing for higher efficiency and consistency in production. This trend is particularly evident in sectors such as automotive and electronics, where precision and speed are paramount. The adoption of robotics and automated welding systems not only improves operational efficiency but also addresses the challenges of labor shortages, making it a crucial factor in the market's growth.

Expansion of Electronics Manufacturing

The rapid expansion of the electronics manufacturing sector is a notable driver for the Resistance Spot Welding Machine Market. As electronic devices become more complex and compact, the need for precise and reliable welding solutions increases. In 2025, the electronics industry is projected to contribute significantly to the demand for resistance spot welding machines, particularly in the production of components such as batteries, circuit boards, and connectors. The ability to perform high-quality welds on small and intricate parts is essential for maintaining product integrity and performance. This trend suggests that manufacturers will increasingly invest in advanced welding technologies to meet the evolving requirements of the electronics market, thereby driving growth in the resistance spot welding machine sector.

Growing Demand for Lightweight Materials

The trend towards lightweight materials in various industries, particularly in automotive and aerospace, significantly influences the Resistance Spot Welding Machine Market. Manufacturers are increasingly utilizing materials such as aluminum and high-strength steel to enhance fuel efficiency and reduce emissions. This shift necessitates advanced welding techniques, as traditional methods may not be suitable for these materials. In 2025, it is anticipated that the use of lightweight materials will drive a notable increase in the demand for resistance spot welding machines, as they offer the precision and strength required for effective bonding. The ability to weld dissimilar materials also presents opportunities for innovation within the market, potentially leading to the development of new machine models tailored to specific applications.

Sustainability Initiatives in Manufacturing

The growing emphasis on sustainability within manufacturing processes is emerging as a key driver for the Resistance Spot Welding Machine Market. As companies strive to reduce their environmental footprint, there is a heightened focus on energy-efficient and waste-reducing technologies. Resistance spot welding machines are often favored for their ability to minimize material waste and energy consumption compared to traditional welding methods. In 2025, it is anticipated that sustainability initiatives will lead to increased investments in advanced welding technologies, as manufacturers seek to comply with regulatory standards and consumer expectations. This shift not only supports environmental goals but also enhances operational efficiency, making it a pivotal factor in the market's evolution.