Rising Investment in Industrial Automation

The trend towards industrial automation is a crucial driver for the Radial Drilling Machine Market. As industries seek to enhance productivity and reduce labor costs, there is a marked shift towards automated solutions. Radial drilling machines equipped with automation features allow for continuous operation and improved accuracy, which are essential in high-volume production environments. Recent reports indicate that the automation market is projected to grow at a CAGR of 10% over the next five years, suggesting a robust demand for automated drilling solutions. This shift not only streamlines operations but also aligns with the broader trend of digital transformation in manufacturing. Consequently, the Radial Drilling Machine Market stands to gain from this increasing investment in automation technologies.

Growing Demand from the Construction Sector

The construction sector is a pivotal driver for the Radial Drilling Machine Market, as the need for precise drilling solutions escalates with the rise of infrastructure projects. With urbanization and population growth, there is an increasing demand for residential and commercial buildings, which in turn necessitates the use of advanced drilling machines. Recent statistics indicate that the construction industry is projected to grow at a CAGR of 5% over the next five years, thereby creating a substantial market for radial drilling machines. These machines are essential for tasks such as drilling holes in steel beams and concrete, which are critical for structural integrity. As construction activities ramp up, the Radial Drilling Machine Market is poised to benefit significantly from this trend.

Increased Focus on Manufacturing Efficiency

Manufacturers are increasingly prioritizing efficiency and productivity, which is a key driver for the Radial Drilling Machine Market. The need to optimize production processes has led to a growing preference for machines that offer versatility and speed. Radial drilling machines, known for their ability to handle various materials and complex drilling tasks, are becoming indispensable in manufacturing settings. Data suggests that companies that have integrated advanced radial drilling solutions have reported a 15% reduction in operational costs. This focus on efficiency not only enhances profitability but also supports sustainability initiatives by minimizing waste. As industries strive for lean manufacturing practices, the Radial Drilling Machine Market is likely to see sustained demand.

Expansion of the Aerospace and Automotive Industries

The aerospace and automotive industries are significant contributors to the Radial Drilling Machine Market, as these sectors require high-precision drilling for components. The increasing complexity of designs and the need for lightweight materials have led to a rise in the use of radial drilling machines, which can accommodate intricate specifications. Recent market analysis indicates that the aerospace sector alone is expected to grow by 4% annually, driving demand for advanced drilling solutions. Additionally, the automotive industry's shift towards electric vehicles necessitates the use of precision drilling for battery components and lightweight structures. This expansion in both sectors is likely to bolster the Radial Drilling Machine Market, as manufacturers seek reliable and efficient drilling technologies.

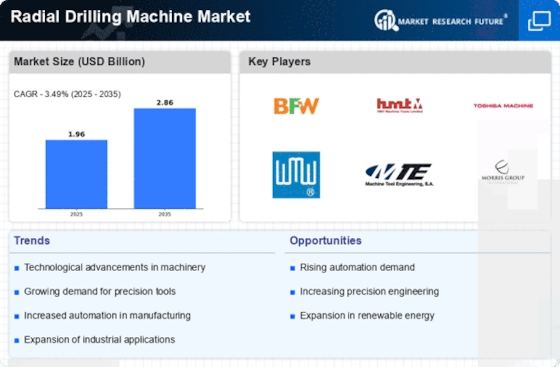

Technological Advancements in Radial Drilling Machines

The Radial Drilling Machine Market is experiencing a surge in technological advancements that enhance operational efficiency and precision. Innovations such as CNC integration and automation are becoming increasingly prevalent, allowing for higher productivity and reduced human error. The introduction of smart technologies, including IoT connectivity, enables real-time monitoring and predictive maintenance, which can significantly lower downtime. According to recent data, the adoption of advanced features in radial drilling machines has led to a 20% increase in production rates across various sectors. As manufacturers continue to invest in R&D, the market is likely to see further enhancements that cater to the evolving needs of industries such as automotive and aerospace, thereby driving growth in the Radial Drilling Machine Market.