Focus on Quality Control

The focus on quality control is emerging as a critical driver in the Production Monitoring Market. With consumers becoming more discerning, manufacturers are compelled to ensure that their products meet stringent quality standards. This emphasis on quality necessitates the implementation of robust monitoring systems that can detect defects and deviations in real-time. Data suggests that organizations with effective quality control measures can reduce production costs by up to 30%. Consequently, there is a growing demand for production monitoring solutions that incorporate advanced quality assurance features, such as automated inspections and predictive analytics. These technologies enable manufacturers to maintain high-quality output while minimizing waste and rework. As the competition intensifies, the ability to deliver superior quality products will likely become a key differentiator in the Production Monitoring Market.

Increased Regulatory Compliance

Increased regulatory compliance is a significant driver shaping the Production Monitoring Market. As governments and regulatory bodies impose stricter guidelines on manufacturing processes, companies are compelled to adopt monitoring solutions that ensure compliance with these regulations. This trend is particularly evident in industries such as pharmaceuticals and food processing, where adherence to safety and quality standards is paramount. Recent reports indicate that non-compliance can result in fines exceeding millions of dollars, prompting organizations to invest in comprehensive monitoring systems. These systems not only facilitate compliance but also enhance transparency and traceability in production processes. By integrating compliance features into their monitoring solutions, manufacturers can mitigate risks and avoid costly penalties, thereby reinforcing the importance of regulatory adherence in the Production Monitoring Market.

Rising Demand for Real-Time Data

The rising demand for real-time data is significantly influencing the Production Monitoring Market. As industries strive for operational excellence, the ability to access and analyze data instantaneously has become crucial. Real-time monitoring allows manufacturers to identify inefficiencies and respond promptly to production anomalies. Recent statistics indicate that organizations utilizing real-time data analytics experience a 20% increase in productivity. This trend is driving investments in production monitoring solutions that offer real-time insights into machine performance, inventory levels, and production schedules. Furthermore, the integration of cloud computing technologies facilitates the storage and analysis of vast amounts of data, making it accessible from anywhere. As a result, companies are increasingly prioritizing real-time data capabilities in their production monitoring strategies, thereby enhancing decision-making processes and operational agility.

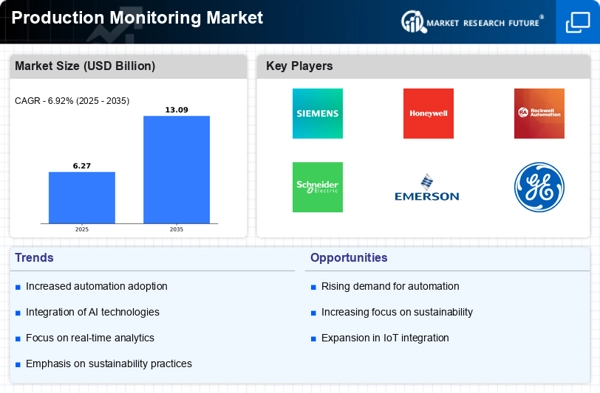

Integration of Automation Technologies

The integration of automation technologies is a pivotal driver in the Production Monitoring Market. As manufacturers increasingly adopt automated systems, the need for real-time monitoring becomes paramount. Automation enhances efficiency and reduces human error, thereby improving overall production quality. According to recent data, the automation sector is projected to grow at a compound annual growth rate of 9.5% through 2027. This growth is likely to propel the demand for advanced production monitoring solutions that can seamlessly integrate with automated systems. Consequently, companies are investing in sophisticated monitoring tools that provide insights into production processes, enabling them to optimize operations and reduce downtime. The emphasis on automation not only streamlines production but also fosters a culture of continuous improvement, which is essential for maintaining competitiveness in the Production Monitoring Market.

Growing Emphasis on Operational Efficiency

The growing emphasis on operational efficiency is a driving force in the Production Monitoring Market. As competition intensifies, manufacturers are increasingly focused on optimizing their production processes to reduce costs and enhance productivity. This focus on efficiency is leading to the adoption of advanced monitoring solutions that provide insights into operational performance. Data indicates that companies implementing production monitoring systems can achieve up to a 25% reduction in operational costs. By leveraging real-time data analytics, manufacturers can identify bottlenecks, streamline workflows, and improve resource allocation. Furthermore, the integration of machine learning algorithms into monitoring systems allows for predictive maintenance, reducing unplanned downtime. As organizations strive for operational excellence, the demand for innovative production monitoring solutions that drive efficiency is likely to grow, underscoring the importance of this trend in the Production Monitoring Market.

Leave a Comment