Technological Innovations

Technological advancements play a pivotal role in shaping the Precision Ball Screw Market. Innovations in materials, design, and manufacturing processes are enhancing the performance and durability of ball screws. For instance, the introduction of advanced coatings and heat treatment processes has improved wear resistance and load capacity, making these components more efficient. Furthermore, the integration of smart technologies, such as IoT and predictive maintenance, is revolutionizing the way precision ball screws are utilized in machinery. This evolution not only increases operational efficiency but also reduces downtime, which is critical for industries reliant on high-performance equipment. As a result, the Precision Ball Screw Market is likely to witness a robust growth trajectory, driven by these technological innovations.

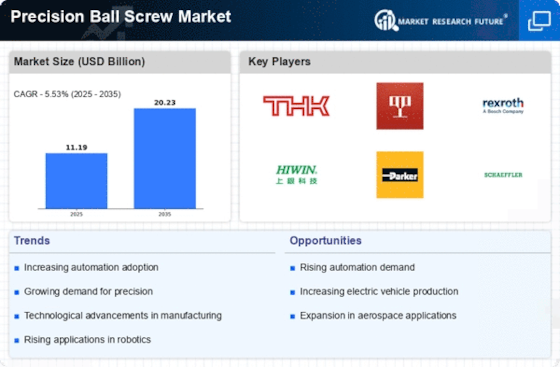

Rising Demand in Automation

The Precision Ball Screw Market is experiencing a notable surge in demand due to the increasing adoption of automation across various sectors. Industries such as manufacturing, aerospace, and robotics are integrating advanced automation technologies to enhance efficiency and precision. This trend is expected to drive the market, as precision ball screws are essential components in automated systems, providing high accuracy and reliability. According to recent data, the automation sector is projected to grow at a compound annual growth rate (CAGR) of approximately 9% over the next five years, further fueling the demand for precision ball screws. As companies strive for operational excellence, the reliance on precision ball screws in automated machinery is likely to intensify, positioning the Precision Ball Screw Market for substantial growth.

Expansion of Electric Vehicles

The Precision Ball Screw Market is experiencing growth driven by the expansion of the electric vehicle (EV) market. As automotive manufacturers increasingly focus on electric mobility, the demand for precision components, including ball screws, is expected to rise. Precision ball screws are utilized in various applications within EVs, such as steering systems and automated assembly processes. The electric vehicle market is projected to grow at a CAGR of approximately 15% over the next decade, indicating a substantial opportunity for the Precision Ball Screw Market. This growth is likely to be fueled by advancements in battery technology and government incentives promoting electric vehicle adoption, further solidifying the role of precision ball screws in this evolving automotive landscape.

Increased Investment in Robotics

The Precision Ball Screw Market is benefiting from increased investment in robotics across multiple sectors. As industries seek to enhance productivity and reduce labor costs, the integration of robotic systems is becoming more prevalent. Precision ball screws are critical components in robotic applications, providing the necessary motion control and accuracy required for tasks ranging from assembly to material handling. Recent data indicates that the robotics market is expected to grow at a CAGR of around 10% in the next few years, which will likely drive demand for precision ball screws. This trend highlights the essential role of the Precision Ball Screw Market in supporting the ongoing evolution of robotics and automation.

Growth in Renewable Energy Sector

The Precision Ball Screw Market is poised to benefit from the burgeoning renewable energy sector. As the world shifts towards sustainable energy sources, the demand for precision components in wind turbines, solar tracking systems, and other renewable technologies is on the rise. Precision ball screws are integral to the operation of these systems, providing the necessary precision and reliability for optimal performance. Recent estimates suggest that the renewable energy market could expand at a CAGR of over 8% in the coming years, which will likely translate into increased demand for precision ball screws. This trend underscores the importance of the Precision Ball Screw Market in supporting the transition to a more sustainable energy landscape.