Rising Industrial Automation

The Global Power Transmission Belting Market Industry is experiencing a surge in demand due to the increasing adoption of industrial automation across various sectors. Industries such as manufacturing, automotive, and food processing are integrating automated systems to enhance productivity and efficiency. This trend is projected to drive the market's growth, with the industry expected to reach 11.8 USD Billion in 2024. As companies seek to optimize operations, the reliance on power transmission belts for conveying power and motion becomes critical, thereby propelling the market forward.

Growth in Renewable Energy Sector

The Global Power Transmission Belting Market Industry is likely to benefit from the expansion of the renewable energy sector. As countries worldwide invest in sustainable energy sources, the demand for power transmission solutions in wind and solar energy applications is increasing. Power transmission belts are essential for the efficient operation of machinery in these sectors. This growth is anticipated to contribute to the market's valuation, potentially reaching 25.4 USD Billion by 2035, as renewable energy projects proliferate and require reliable power transmission systems.

Expansion of Manufacturing Facilities

The Global Power Transmission Belting Market Industry is witnessing growth due to the expansion of manufacturing facilities globally. As economies recover and industrial activities ramp up, new manufacturing plants are being established, particularly in emerging markets. This expansion necessitates the installation of power transmission systems, including belts, to ensure smooth operations. Consequently, the market is likely to experience increased demand, aligning with the overall industrial growth and the need for efficient power transmission solutions.

Technological Advancements in Materials

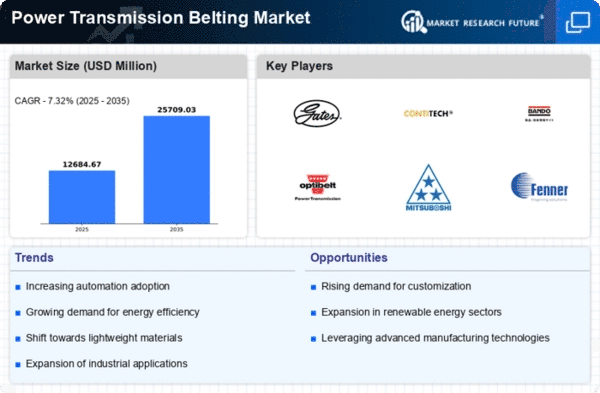

Innovations in materials used for power transmission belts are significantly influencing the Global Power Transmission Belting Market Industry. The development of high-performance materials, such as thermoplastic elastomers and advanced composites, enhances the durability and efficiency of belts. These advancements lead to longer service life and reduced maintenance costs, making them attractive to industries. As a result, the market is poised for growth, with a projected CAGR of 7.19% from 2025 to 2035, reflecting the industry's adaptation to technological improvements.

Increasing Demand from Automotive Sector

The automotive sector is a pivotal driver for the Global Power Transmission Belting Market Industry. With the rise in vehicle production and the shift towards electric vehicles, the demand for efficient power transmission solutions is escalating. Power transmission belts are integral to various automotive applications, including engine systems and accessory drives. This demand is expected to bolster the market, contributing to its growth trajectory as manufacturers seek reliable components to enhance vehicle performance and efficiency.