Advancements in Textile Industry

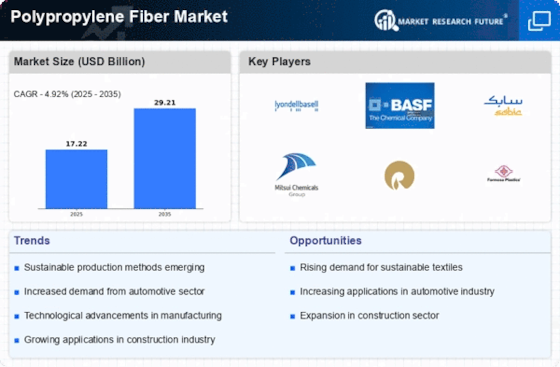

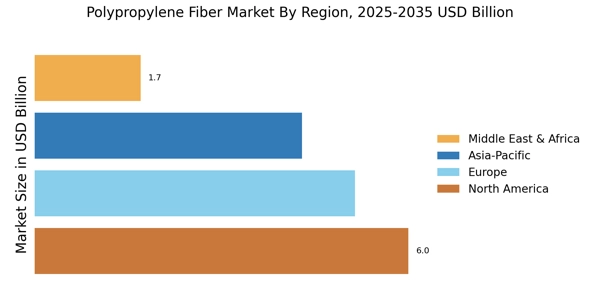

The textile industry is undergoing a transformation with the increasing utilization of polypropylene fibers in various applications, including apparel and home textiles. These fibers are favored for their moisture-wicking properties and resistance to staining, making them ideal for activewear and outdoor clothing. The polypropylene fiber market is projected to benefit from this trend, with a compound annual growth rate of around 4% anticipated in the textile segment. Furthermore, the rise of eco-friendly textiles is prompting manufacturers to explore sustainable options, and polypropylene fibers, being recyclable, align well with these initiatives. This shift towards innovative textile solutions is likely to enhance the market's appeal and broaden its consumer base.

Growth in Automotive Applications

The automotive industry is increasingly incorporating polypropylene fibers into vehicle manufacturing, primarily for interior components and lightweight structures. This shift is largely attributed to the fibers' lightweight nature, which contributes to improved fuel efficiency and reduced emissions. The polypropylene fiber market is expected to expand as automotive manufacturers seek to meet stringent environmental regulations while enhancing vehicle performance. Recent data suggests that the use of polypropylene fibers in automotive applications could lead to a reduction in overall vehicle weight by up to 10%, thereby significantly impacting fuel consumption. As electric vehicles gain popularity, the demand for lightweight materials, including polypropylene fibers, is likely to rise, further driving market growth.

Increased Focus on Waste Management

The growing emphasis on waste management and recycling is influencing the polypropylene fiber market positively. As industries and consumers alike become more environmentally conscious, the demand for recycled polypropylene fibers is on the rise. These fibers are increasingly being used in various applications, including geotextiles and non-woven fabrics, which are essential for effective waste management solutions. Recent statistics indicate that the recycling rate of polypropylene has improved, with projections suggesting a potential increase in the availability of recycled fibers in the market. This trend not only supports sustainability efforts but also provides a cost-effective alternative for manufacturers, thereby enhancing the overall market dynamics.

Rising Demand in Construction Sector

The construction sector is experiencing a notable surge in demand for polypropylene fiber, primarily due to its advantageous properties such as durability and resistance to moisture. This trend is particularly evident in the production of concrete, where polypropylene fibers are utilized to enhance tensile strength and reduce cracking. The polypropylene fiber market is projected to witness a growth rate of approximately 5% annually, driven by the increasing adoption of these fibers in various construction applications. As urbanization accelerates, the need for robust building materials becomes paramount, further propelling the demand for polypropylene fibers. Additionally, the integration of these fibers in asphalt mixtures is gaining traction, indicating a broader application scope within the construction industry.

Technological Innovations in Production

Technological advancements in the production of polypropylene fibers are significantly shaping the market landscape. Innovations such as improved spinning techniques and enhanced polymerization processes are leading to the development of high-performance fibers with superior characteristics. The polypropylene fiber market is likely to experience growth as manufacturers adopt these technologies to meet the evolving demands of various sectors, including automotive, construction, and textiles. Enhanced production efficiency and reduced energy consumption are additional benefits associated with these innovations, which could potentially lower production costs. As a result, the market may witness an influx of new entrants and increased competition, further stimulating growth and diversification within the industry.