Rising Demand in Automotive Sector

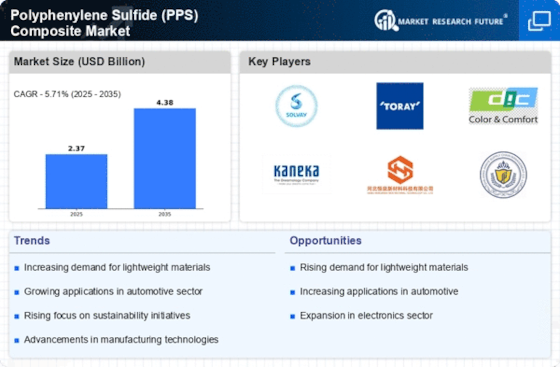

The automotive sector is experiencing a notable increase in the adoption of lightweight materials, which enhances fuel efficiency and reduces emissions. Polyphenylene Sulfide (PPS) Composite Market is benefiting from this trend, as PPS composites offer excellent thermal stability and chemical resistance, making them suitable for various automotive components. The market for PPS in automotive applications is projected to grow significantly, with estimates suggesting a compound annual growth rate of over 5% in the coming years. This growth is driven by the need for high-performance materials that can withstand harsh environments while contributing to overall vehicle performance. As manufacturers seek to comply with stringent environmental regulations, the demand for PPS composites is likely to rise, positioning the Polyphenylene Sulfide (PPS) Composite Market favorably within the automotive landscape.

Growing Demand in Aerospace Applications

The aerospace industry is increasingly turning to advanced materials to improve performance and reduce weight. Polyphenylene Sulfide (PPS) Composite Market is positioned to benefit from this trend, as PPS composites offer exceptional mechanical properties and resistance to extreme temperatures. The demand for lightweight and durable materials in aerospace applications is projected to grow, with estimates suggesting a market expansion of around 7% in the next few years. This growth is driven by the need for materials that can withstand the rigors of flight while contributing to fuel efficiency. As aerospace manufacturers seek to enhance the performance of their aircraft, the Polyphenylene Sulfide (PPS) Composite Market is likely to see increased adoption of PPS composites in various components, including structural parts and thermal insulation.

Sustainability and Regulatory Compliance

The increasing emphasis on sustainability and regulatory compliance is shaping the Polyphenylene Sulfide (PPS) Composite Market. As industries strive to reduce their environmental footprint, the demand for eco-friendly materials is on the rise. PPS composites, known for their durability and recyclability, are becoming a preferred choice for manufacturers looking to meet sustainability goals. The market is likely to see a growth rate of approximately 4% as companies seek materials that align with environmental regulations and consumer preferences. This shift towards sustainable practices is prompting the Polyphenylene Sulfide (PPS) Composite Market to innovate and develop new formulations that enhance the environmental profile of PPS composites, thereby attracting a broader customer base.

Advancements in Manufacturing Technologies

Recent advancements in manufacturing technologies are significantly impacting the Polyphenylene Sulfide (PPS) Composite Market. Innovations such as 3D printing and advanced molding techniques are enabling the production of complex geometries and customized solutions. These technologies allow for greater design flexibility and efficiency, which is particularly beneficial in industries such as automotive and aerospace. The ability to produce PPS composites with enhanced properties and reduced lead times is likely to drive market growth, with projections indicating a potential increase in demand of around 5% annually. As manufacturers adopt these new technologies, the Polyphenylene Sulfide (PPS) Composite Market is expected to evolve, offering more tailored solutions to meet specific application requirements.

Increased Focus on Electronics and Electrical Applications

The electronics and electrical industries are increasingly utilizing advanced materials to enhance performance and reliability. Polyphenylene Sulfide (PPS) Composite Market is witnessing a surge in demand due to the material's excellent dielectric properties and thermal stability. PPS composites are particularly favored for applications in connectors, insulators, and circuit boards, where high performance is essential. The market for PPS in electrical applications is expected to expand, with projections indicating a growth rate of approximately 6% annually. This trend is fueled by the ongoing miniaturization of electronic devices and the need for materials that can withstand high temperatures and harsh chemical environments. As the electronics sector continues to evolve, the Polyphenylene Sulfide (PPS) Composite Market is likely to play a crucial role in meeting the demands for innovative and reliable components.