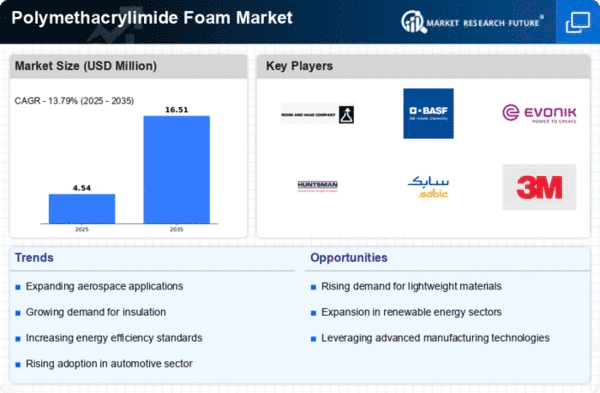

Market Growth Projections

The Global Polymethacrylimide Foam Market Industry is projected to experience substantial growth over the next decade. With a market valuation of 108.2 USD Million in 2024, the industry is expected to expand significantly, reaching 213.4 USD Million by 2035. This growth trajectory suggests a compound annual growth rate (CAGR) of 6.37% from 2025 to 2035. Various factors, including advancements in technology, increasing demand for lightweight materials, and regulatory support for sustainable solutions, are likely to contribute to this upward trend. The market's expansion reflects the growing recognition of polymethacrylimide foam's benefits across multiple sectors.

Growing Demand in Aerospace Sector

The Global Polymethacrylimide Foam Market Industry is experiencing a surge in demand driven by the aerospace sector. This material is favored for its lightweight and thermal insulation properties, which are crucial for aircraft design. As airlines and manufacturers seek to enhance fuel efficiency and reduce emissions, the adoption of polymethacrylimide foam is likely to increase. In 2024, the market is projected to reach 108.2 USD Million, reflecting the aerospace industry's commitment to innovative materials. The trend towards lightweight materials in aviation is expected to continue, potentially propelling the market further as manufacturers aim for sustainability and performance improvements.

Increasing Focus on Lightweight Materials

The Global Polymethacrylimide Foam Market Industry is benefiting from an increasing focus on lightweight materials across various industries. Lightweight materials contribute to improved fuel efficiency and performance in automotive and aerospace applications. As manufacturers strive to meet regulatory standards and consumer expectations for sustainability, the adoption of polymethacrylimide foam is likely to grow. The projected CAGR of 6.37% from 2025 to 2035 indicates a robust market trajectory, as industries recognize the advantages of using lightweight materials in their designs. This trend is expected to foster innovation and drive further research into advanced foam applications.

Regulatory Support for Sustainable Materials

Regulatory frameworks promoting sustainable materials are playing a crucial role in shaping the Global Polymethacrylimide Foam Market Industry. Governments worldwide are implementing policies that encourage the use of eco-friendly materials in construction, automotive, and aerospace sectors. This regulatory support is likely to enhance the adoption of polymethacrylimide foam, as it aligns with sustainability goals. The anticipated growth in market size to 213.4 USD Million by 2035 reflects the increasing alignment of industry practices with regulatory expectations. As companies seek to comply with these regulations, the demand for sustainable materials such as polymethacrylimide foam is expected to rise.

Rising Demand for Energy-Efficient Solutions

The Global Polymethacrylimide Foam Market Industry is witnessing a rising demand for energy-efficient solutions, particularly in the construction and automotive sectors. As global energy consumption continues to rise, there is a pressing need for materials that enhance energy efficiency. Polymethacrylimide foam, with its superior insulation properties, is increasingly being utilized in energy-efficient building designs and automotive applications. This trend is likely to contribute to the market's growth, with projections indicating a market size of 108.2 USD Million in 2024. The emphasis on sustainability and energy conservation is expected to further bolster the demand for this innovative material.

Advancements in Thermal Insulation Technologies

Technological advancements in thermal insulation are significantly influencing the Global Polymethacrylimide Foam Market Industry. The foam's exceptional thermal resistance makes it suitable for various applications, including building and construction, automotive, and electronics. As energy efficiency regulations become more stringent globally, the demand for effective insulation materials is likely to rise. This trend is expected to contribute to a market valuation of 213.4 USD Million by 2035. The integration of polymethacrylimide foam in energy-efficient designs may enhance building performance, thereby driving its adoption across multiple sectors.