Growth in the Lubricants Market

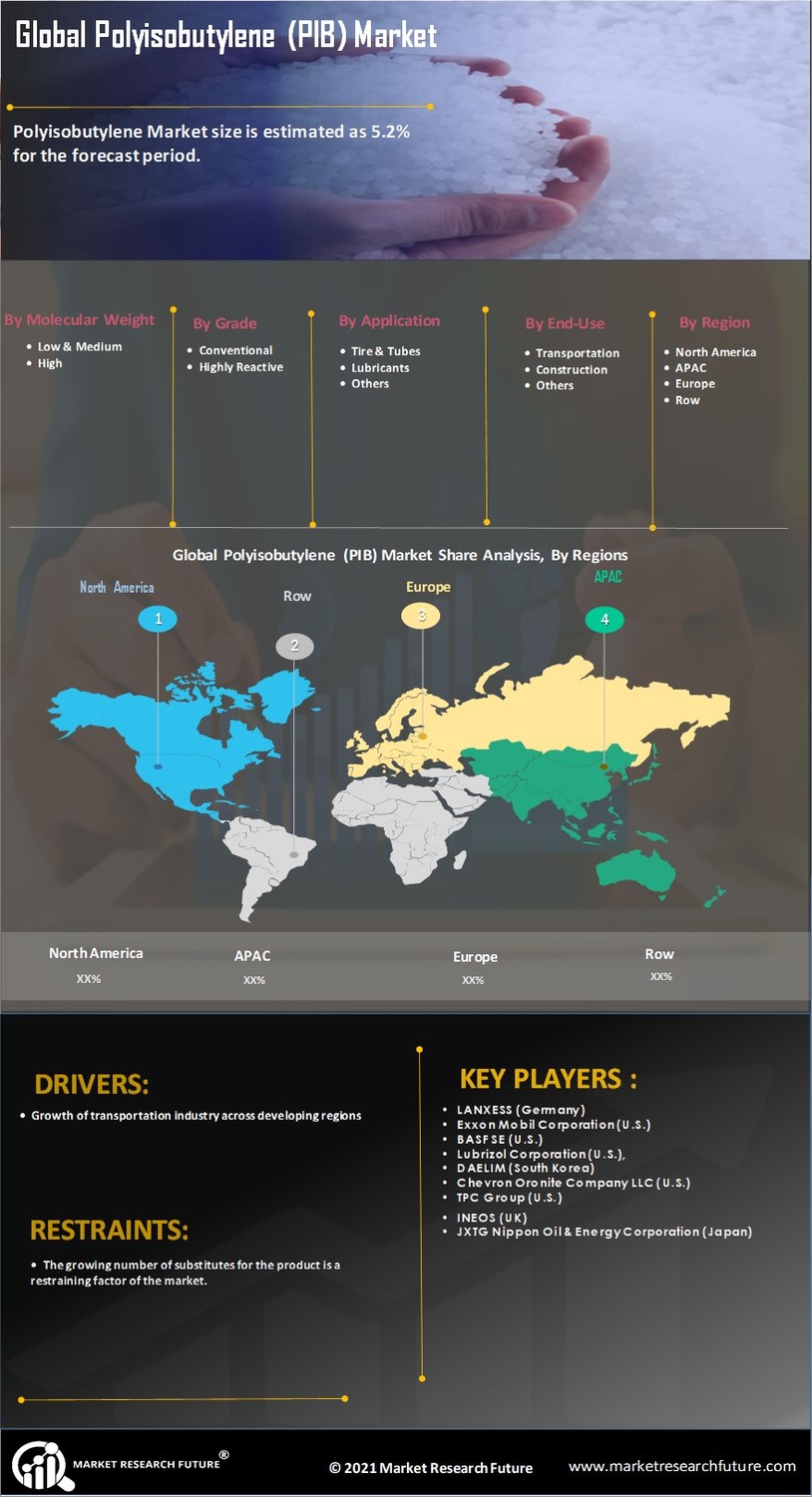

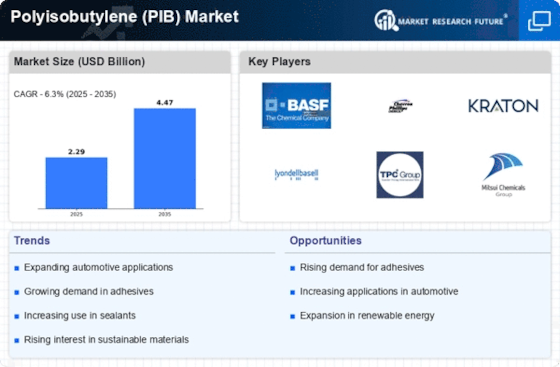

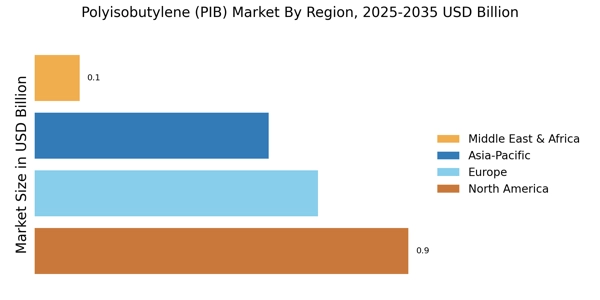

The growth in the lubricants market serves as a significant driver for the Polyisobutylene Market. PIB is widely used as a base oil in various lubricant formulations due to its excellent viscosity index and thermal stability. The Polyisobutylene Market (PIB) is anticipated to witness a steady growth trajectory, with a projected value exceeding 200 billion dollars by 2025. This growth is likely to be fueled by the increasing demand for high-performance lubricants in automotive and industrial applications. As industries seek to improve efficiency and reduce maintenance costs, the adoption of PIB-based lubricants may become more prevalent, thereby enhancing the PIB market's prospects.

Expansion in the Automotive Sector

The automotive sector's expansion is a crucial driver for the Polyisobutylene Market. PIB is increasingly utilized in tire manufacturing due to its superior properties, including low permeability to gases and excellent aging stability. As the automotive industry continues to evolve, with a focus on enhancing fuel efficiency and reducing emissions, the demand for high-performance materials like PIB is expected to rise. The tire market alone is projected to reach a valuation of over 300 billion dollars by 2026, indicating a substantial opportunity for PIB manufacturers. Additionally, the shift towards electric vehicles may further increase the demand for PIB, as these vehicles require advanced materials to meet performance and safety standards.

Rising Demand for Adhesives and Sealants

The increasing demand for adhesives and sealants across various industries is a pivotal driver for the Polyisobutylene Market. PIB's unique properties, such as its excellent adhesion, flexibility, and resistance to moisture, make it an ideal choice for applications in construction, automotive, and packaging sectors. The adhesives and sealants market is projected to grow significantly, with estimates suggesting a compound annual growth rate of around 5% over the next few years. This growth is likely to bolster the PIB market, as manufacturers seek high-performance materials that can enhance product durability and performance. Furthermore, the trend towards eco-friendly and sustainable products may lead to increased adoption of PIB-based adhesives, further propelling the market forward.

Technological Innovations in Polymer Production

Technological innovations in polymer production are driving advancements in the Polyisobutylene Market. The development of new polymerization techniques and catalysts has led to the production of PIB with enhanced properties, such as improved molecular weight and better processing characteristics. These innovations not only increase the efficiency of PIB production but also expand its application range across various industries, including automotive, construction, and consumer goods. As manufacturers continue to invest in research and development, the PIB market is likely to benefit from the introduction of novel PIB grades that meet specific performance requirements, thus attracting a broader customer base.

Increasing Regulatory Support for Synthetic Polymers

Increasing regulatory support for synthetic polymers is emerging as a key driver for the Polyisobutylene Market. Governments and regulatory bodies are implementing policies that promote the use of high-performance synthetic materials in various applications, including automotive and construction. This regulatory environment encourages manufacturers to adopt PIB due to its favorable properties and compliance with environmental standards. As industries strive to meet stringent regulations regarding emissions and product safety, the demand for PIB is expected to rise. Furthermore, the emphasis on sustainability may lead to increased investment in PIB production technologies, enhancing the market's growth potential.