Market Growth Projections

The Global Polyetherimide Market Industry is poised for substantial growth, with projections indicating a market size of 670 USD Million in 2024 and an anticipated increase to 1220.2 USD Million by 2035. This growth trajectory reflects a compound annual growth rate (CAGR) of 5.6% from 2025 to 2035. The increasing adoption of polyetherimide across various sectors, including aerospace, automotive, and electronics, suggests a robust demand for this high-performance polymer. As industries continue to innovate and prioritize advanced materials, the polyetherimide market is likely to thrive, driven by technological advancements and evolving consumer preferences.

Advancements in Electronics

In the realm of electronics, the Global Polyetherimide Market Industry is witnessing substantial growth due to the increasing adoption of polyetherimide in electrical insulation and components. The material's excellent dielectric properties and thermal stability make it suitable for applications in circuit boards and connectors. As consumer electronics evolve, the demand for high-performance materials is likely to rise, further propelling the market. The anticipated growth rate of 5.6% CAGR from 2025 to 2035 underscores the potential for polyetherimide to play a pivotal role in the electronics sector, catering to the needs of modern technology.

Growth in Automotive Applications

The automotive industry significantly influences the Global Polyetherimide Market Industry, as manufacturers seek lightweight materials to enhance fuel efficiency and reduce emissions. Polyetherimide Market's durability and resistance to chemicals make it an attractive option for various automotive components, including interior parts and electrical housings. With the global push towards electric vehicles, the demand for high-performance materials is expected to escalate. This trend aligns with the market's projected growth, reaching 1220.2 USD Million by 2035, indicating a strong correlation between automotive advancements and polyetherimide utilization.

Rising Demand in Aerospace Sector

The Global Polyetherimide Market Industry experiences a notable surge in demand from the aerospace sector, where lightweight and high-performance materials are crucial. Polyetherimide Market's exceptional thermal stability and mechanical strength make it an ideal choice for aircraft components, contributing to fuel efficiency and reduced emissions. As the aerospace industry continues to innovate, the demand for polyetherimide is projected to grow significantly, with the market expected to reach 670 USD Million in 2024. This trend indicates a robust growth trajectory, driven by the need for advanced materials that can withstand extreme conditions while ensuring safety and performance.

Increasing Focus on Sustainability

Sustainability initiatives are reshaping the Global Polyetherimide Market Industry, as industries strive to reduce their environmental footprint. Polyetherimide Market, being a recyclable material, aligns with the growing emphasis on eco-friendly practices. Companies are increasingly adopting polyetherimide for applications that require both performance and sustainability, such as packaging and consumer goods. This shift towards sustainable materials is likely to drive demand, as organizations seek to meet regulatory requirements and consumer expectations. The market's growth trajectory suggests that sustainability will play a crucial role in shaping the future of polyetherimide applications.

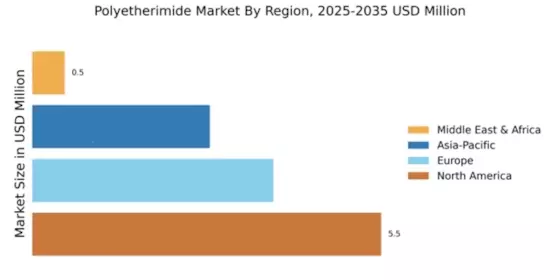

Emerging Markets and Industrial Growth

Emerging markets are becoming pivotal in the Global Polyetherimide Market Industry, as industrialization accelerates in regions such as Asia-Pacific and Latin America. These regions are witnessing a surge in demand for high-performance materials across various sectors, including healthcare, aerospace, and automotive. The increasing investments in infrastructure and manufacturing capabilities are expected to bolster the demand for polyetherimide, contributing to the market's expansion. As these markets develop, the potential for polyetherimide applications appears promising, indicating a favorable outlook for the industry in the coming years.