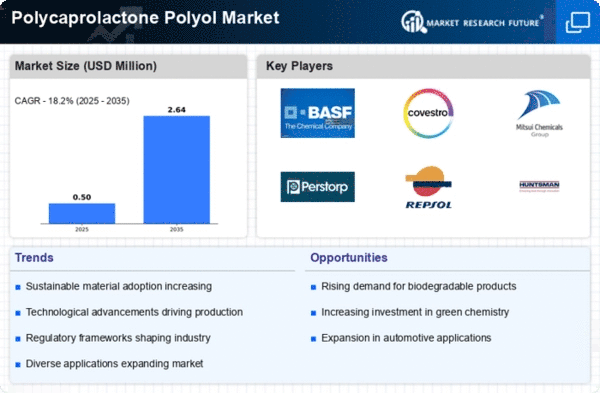

Market Growth Projections

The Global Polycaprolactone Polyol Market Industry is poised for substantial growth, with projections indicating a market size of 700 USD Million in 2024. This growth trajectory is expected to accelerate, with estimates suggesting a market value of 2268.2 USD Million by 2035. The compound annual growth rate of 11.28% from 2025 to 2035 reflects the increasing adoption of polycaprolactone polyol across various sectors, including automotive, packaging, and medical applications. The anticipated expansion underscores the material's versatility and the growing demand for sustainable alternatives in the global market.

Advancements in Polymer Technology

Technological advancements in polymer science significantly influence the Global Polycaprolactone Polyol Market Industry. Innovations in production techniques and formulations enhance the performance characteristics of polycaprolactone polyol, making it suitable for a wider range of applications. For instance, improvements in its mechanical properties and thermal stability allow for its use in high-performance coatings and adhesives. These advancements not only increase the versatility of polycaprolactone polyol but also attract investments in research and development. As a result, the market is expected to grow at a compound annual growth rate of 11.28% from 2025 to 2035, reflecting the industry's commitment to continuous improvement and innovation.

Rising Demand for Biodegradable Materials

The Global Polycaprolactone Polyol Market Industry experiences a surge in demand for biodegradable materials, driven by increasing environmental awareness. As industries seek sustainable alternatives to conventional plastics, polycaprolactone polyol emerges as a viable option due to its biodegradability and eco-friendliness. This trend is particularly evident in packaging, automotive, and consumer goods sectors, where companies are actively pursuing greener solutions. The market is projected to reach 700 USD Million in 2024, reflecting a growing commitment to sustainability. Furthermore, the anticipated growth trajectory suggests that by 2035, the market could expand to 2268.2 USD Million, indicating a robust shift towards environmentally responsible materials.

Growing Applications in the Medical Sector

The Global Polycaprolactone Polyol Market Industry benefits from expanding applications in the medical field, where its biocompatibility and biodegradability are highly valued. Polycaprolactone polyol is increasingly utilized in the production of drug delivery systems, sutures, and tissue engineering scaffolds. These applications are driven by the need for materials that can safely interact with biological systems while minimizing environmental impact. The medical sector's growing reliance on such materials is indicative of a broader trend towards sustainable healthcare solutions. As the market evolves, it is poised for significant growth, with projections indicating a potential market size of 2268.2 USD Million by 2035.

Regulatory Support for Sustainable Practices

Regulatory frameworks promoting sustainable practices significantly impact the Global Polycaprolactone Polyol Market Industry. Governments worldwide are increasingly implementing policies that encourage the use of biodegradable materials in various sectors, including packaging and construction. Such regulations not only create a favorable environment for polycaprolactone polyol but also stimulate demand across industries seeking compliance with environmental standards. This regulatory support is expected to drive market growth, with projections indicating a market size of 700 USD Million in 2024. As sustainability becomes a priority for policymakers, the market is likely to expand further, with potential growth reaching 2268.2 USD Million by 2035.

Increased Investment in Research and Development

Investment in research and development plays a crucial role in shaping the Global Polycaprolactone Polyol Market Industry. Companies are increasingly allocating resources to explore new applications and improve existing formulations of polycaprolactone polyol. This focus on R&D not only enhances product performance but also fosters innovation in sustainable practices. For example, research initiatives aimed at optimizing production processes can lead to cost reductions and improved environmental outcomes. As a result, the market is likely to witness a steady growth trajectory, with an expected compound annual growth rate of 11.28% from 2025 to 2035, reflecting the industry's commitment to advancing polycaprolactone polyol technologies.