Market Trends

Key Emerging Trends in the Pneumatic Components Market

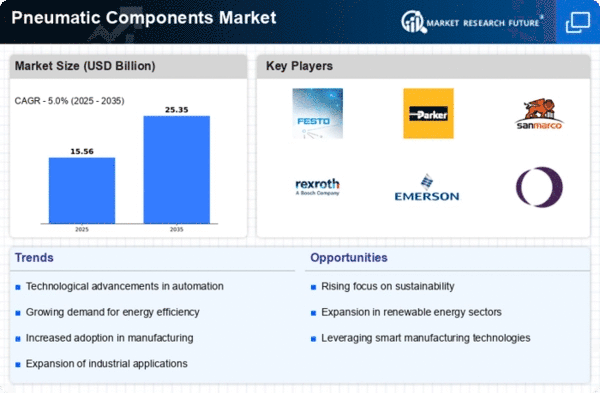

Pneumatic components play a crucial role in various industries, particularly in manufacturing, where the demand for safe and precise processes is on the rise. This is driven by the need for efficient automation and the utilization of compressed air. The adoption of pneumatic devices has become increasingly common among machine manufacturers and end users, offering a cost-effective and efficient means of achieving motion and actuation in a wide range of systems. Pneumatics provides original equipment manufacturers (OEMs) and end users with reliable, lightweight, and proven techniques to enhance the safety of their equipment. In manufacturing and other industries, pneumatics is instrumental in executing critical safety functions such as limiting speed, reducing pressure and force, safely releasing energy, and ensuring a secure direction of travel or preventing undesired movement. Many manufacturers specializing in pneumatic systems are actively engaged in developing technologies that prioritize machine safety. Additionally, they focus on improving energy efficiency, connectivity, and monitoring plant automation, which aids in maintenance planning and operational efficiency. Pneumatic components exhibit various features and advantages that make them the preferred choice for numerous applications. The rapid adoption of the Industrial Internet of Things (IIoT) has further propelled the significance of pneumatic technology. With its capabilities in tracking and measurement, pneumatics has become increasingly functional and commercially viable, providing valuable insights into machine operation and device performance. During the design and development phase, both machine safety and operation enhancements emerge as critical considerations. Managing stops and restarts effectively is essential for machine safety and integration. This necessitates well-designed programs, including pneumatic systems, to enable a smooth restart of the machine, returning to a known safe position and resuming the automatic cycle with minimal operator intervention. The demand for precisely crafted programs that ensure safety and streamline operations is expected to be a driving force behind the growth of the global pneumatic components market in the forecast period. the widespread adoption of pneumatic components stems from their pivotal role in ensuring safe and precise processes, aligning with the increasing demand for energy-conscious automation in various industries. As technology advances, the integration of pneumatics with the Industrial Internet of Things enhances its functionality and commercial viability, providing valuable insights for machine operation and device performance. The emphasis on machine safety and operation enhancements, particularly in designing effective stop and restart programs, is anticipated to fuel the growth of the global pneumatic components market in the foreseeable future.

Leave a Comment