Cost Efficiency

Cost efficiency is a driving force behind the adoption of plastic rigid IBCs in various industries, influencing the Plastic Rigid IBC Market. The use of IBCs can significantly reduce packaging and transportation costs compared to traditional packaging methods. Their reusable nature allows companies to minimize waste and lower overall expenses. Additionally, the lightweight design of plastic IBCs contributes to reduced shipping costs, making them an attractive option for businesses looking to optimize their supply chain. As companies increasingly focus on cost reduction strategies, the demand for plastic rigid IBCs is expected to rise, potentially leading to a market growth rate of 6% annually. This emphasis on cost efficiency underscores the importance of plastic rigid IBCs in modern logistics and supply chain management.

Regulatory Compliance

Regulatory compliance is emerging as a crucial driver for the Plastic Rigid IBC Market. Governments worldwide are implementing stringent regulations regarding the safe handling and transportation of hazardous materials. This has led to an increased demand for IBCs that meet specific safety and environmental standards. Manufacturers are compelled to innovate and produce IBCs that comply with these regulations, thereby ensuring the safety of their operations. The market is likely to see a surge in demand for certified IBCs, particularly in the chemical and pharmaceutical sectors, where compliance is non-negotiable. This trend suggests that adherence to regulatory frameworks will play a vital role in shaping the future of the Plastic Rigid IBC Market.

Technological Innovations

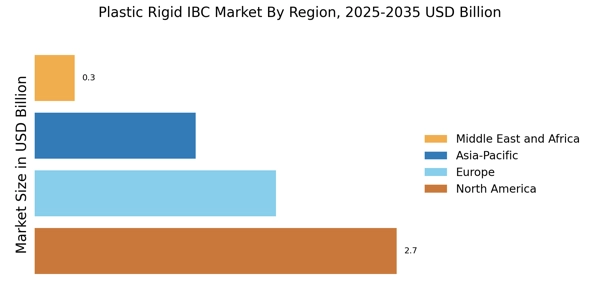

Technological advancements are reshaping the landscape of the Plastic Rigid IBC Market. Innovations in manufacturing processes, such as blow molding and injection molding, have led to the production of more durable and lightweight IBCs. These advancements not only improve the efficiency of transportation and storage but also reduce costs for manufacturers and end-users. Furthermore, the incorporation of smart technologies, such as IoT sensors, is enhancing the functionality of IBCs by providing real-time monitoring of contents. This trend is expected to drive market growth, with estimates suggesting that the market could reach a valuation of USD 2 billion by 2026. The continuous evolution of technology in this sector indicates a promising future for the Plastic Rigid IBC Market.

Sustainability Initiatives

The increasing emphasis on sustainability appears to be a pivotal driver for the Plastic Rigid IBC Market. Companies are increasingly adopting eco-friendly practices, which include the use of recyclable materials in the production of Intermediate Bulk Containers (IBCs). This shift not only aligns with regulatory requirements but also caters to the growing consumer demand for sustainable packaging solutions. As a result, the market for plastic rigid IBCs is projected to witness a compound annual growth rate (CAGR) of approximately 5% over the next few years. The integration of sustainable practices into the supply chain is likely to enhance brand loyalty and customer satisfaction, thereby propelling the growth of the Plastic Rigid IBC Market.

Diverse Industry Applications

The versatility of plastic rigid IBCs across various sectors is a significant driver for the Plastic Rigid IBC Market. These containers are utilized in industries such as chemicals, food and beverage, pharmaceuticals, and agriculture, among others. The ability to safely transport and store a wide range of materials, including hazardous substances, has made IBCs indispensable in many supply chains. For instance, the food and beverage sector is increasingly adopting IBCs for bulk storage of liquids, which is projected to grow at a CAGR of 4.5% through 2025. This diverse applicability not only broadens the market base but also enhances the resilience of the Plastic Rigid IBC Market against economic fluctuations.