Cost Efficiency

Cost considerations are increasingly influencing the choices made within the Plastic Formwork Market. The use of plastic formwork can lead to substantial savings in both material and labor costs. Unlike traditional materials, plastic formwork is reusable, which reduces the need for continuous procurement of new materials. Additionally, its lightweight nature allows for easier handling and quicker installation, further driving down labor expenses. Market data suggests that projects utilizing plastic formwork can achieve up to a 25% reduction in overall costs. As construction firms strive to optimize budgets while maintaining quality, the cost efficiency of plastic formwork is likely to enhance its market presence.

Regulatory Support

Regulatory frameworks promoting the use of innovative construction materials are playing a significant role in shaping the Plastic Formwork Market. Governments and regulatory bodies are increasingly endorsing sustainable building practices, which include the use of plastic formwork. Incentives such as tax breaks and grants for using eco-friendly materials are becoming more common, encouraging construction firms to adopt plastic formwork solutions. This regulatory support not only fosters innovation but also enhances market accessibility for plastic formwork products. As these policies continue to evolve, they are expected to bolster the growth of the Plastic Formwork Market, making it a more viable option for construction projects.

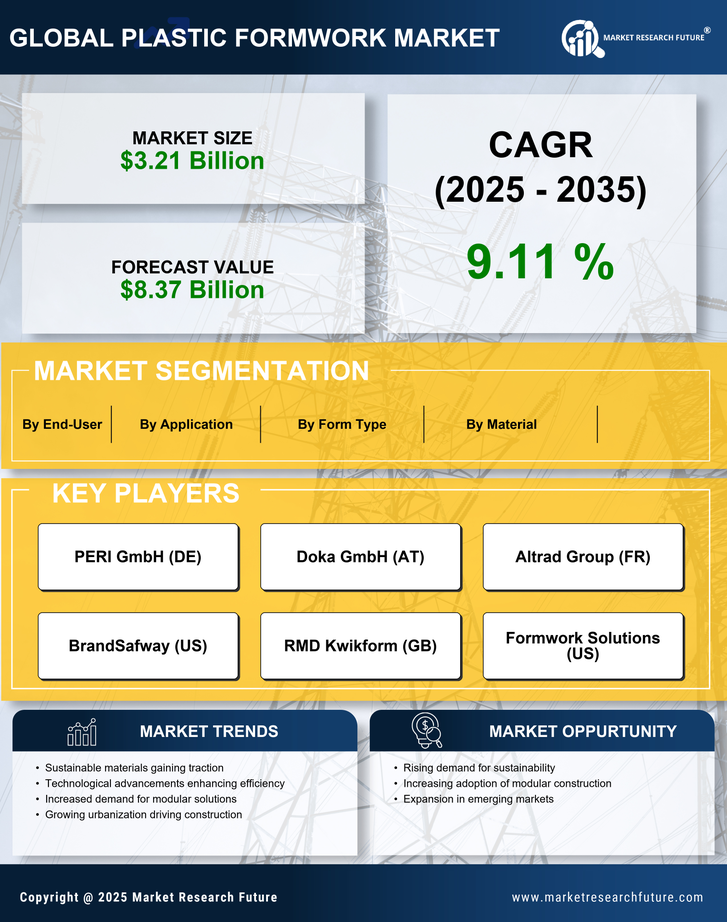

Urbanization Trends

Rapid urbanization is a critical factor propelling the Plastic Formwork Market. As urban areas expand, the demand for residential and commercial infrastructure is surging. This trend necessitates efficient construction methods that can accommodate the increasing pace of development. Plastic formwork offers advantages such as lightweight design and ease of handling, which are particularly beneficial in urban settings where space and time are often constrained. Market analysis indicates that urbanization could lead to a 15% increase in construction activities over the next few years. Consequently, the Plastic Formwork Market is poised to capitalize on this growth, as builders seek efficient solutions to meet urban demands.

Technological Innovations

Technological advancements in the construction industry are significantly influencing the Plastic Formwork Market. Innovations such as 3D printing and advanced manufacturing techniques are enhancing the efficiency and precision of plastic formwork systems. These technologies enable the production of customized formwork solutions that cater to specific project requirements, thereby improving overall project timelines and reducing labor costs. Market data suggests that the integration of technology in construction could lead to a 20% increase in productivity. As these innovations continue to evolve, they are expected to drive the demand for plastic formwork, making it a more attractive option for modern construction projects.

Sustainability Initiatives

The increasing emphasis on sustainability within the construction sector appears to be a pivotal driver for the Plastic Formwork Market. As environmental concerns gain traction, construction companies are increasingly seeking materials that minimize waste and reduce carbon footprints. Plastic formwork, being reusable and recyclable, aligns well with these sustainability goals. Reports indicate that the adoption of sustainable construction practices could lead to a 30% reduction in material waste. This trend not only enhances the appeal of plastic formwork but also positions it as a preferred choice among environmentally conscious builders. Consequently, the Plastic Formwork Market is likely to experience growth as more stakeholders prioritize eco-friendly solutions.