Emergence of Biopharmaceuticals

The emergence of biopharmaceuticals is reshaping the Pharmaceutical Hot Melt Extrusion Market. As biopharmaceuticals gain traction due to their efficacy in treating complex diseases, the need for specialized formulation techniques becomes apparent. Hot melt extrusion offers a viable solution for the formulation of these complex molecules, ensuring stability and bioavailability. The biopharmaceutical market is projected to grow significantly, with estimates suggesting it could reach USD 500 billion by 2025. This growth presents an opportunity for the Pharmaceutical Hot Melt Extrusion Market to adapt and cater to the unique requirements of biopharmaceutical formulations.

Growing Focus on Generic Drug Production

The Pharmaceutical Hot Melt Extrusion Market is significantly influenced by the growing focus on generic drug production. As patent expirations for major pharmaceuticals occur, there is a surge in the development of generic alternatives. Hot melt extrusion plays a crucial role in the formulation of these generics, allowing for cost-effective production while maintaining quality. The generic drug market is expected to reach a valuation of over USD 400 billion by 2026, highlighting the potential for hot melt extrusion technologies to support this expansion. This trend not only enhances accessibility to medications but also drives innovation within the Pharmaceutical Hot Melt Extrusion Market.

Regulatory Support for Innovative Formulations

Regulatory bodies are increasingly supportive of innovative formulation technologies, which is positively impacting the Pharmaceutical Hot Melt Extrusion Market. Initiatives aimed at streamlining the approval process for new drug formulations encourage pharmaceutical companies to adopt hot melt extrusion techniques. This regulatory support is essential for fostering innovation and ensuring that new therapies reach the market efficiently. As regulations evolve to accommodate advanced manufacturing processes, the Pharmaceutical Hot Melt Extrusion Market is likely to benefit from enhanced credibility and acceptance, further driving its growth.

Increased Investment in Research and Development

Investment in research and development (R&D) within the Pharmaceutical Hot Melt Extrusion Market is on the rise, as companies seek to innovate and improve their product offerings. This investment is crucial for developing new formulations and enhancing existing technologies. The pharmaceutical sector has allocated approximately 15% of its revenue to R&D, indicating a strong commitment to advancing drug formulation techniques. As companies strive to meet regulatory requirements and consumer expectations, the emphasis on R&D is likely to foster advancements in hot melt extrusion processes, thereby benefiting the Pharmaceutical Hot Melt Extrusion Market.

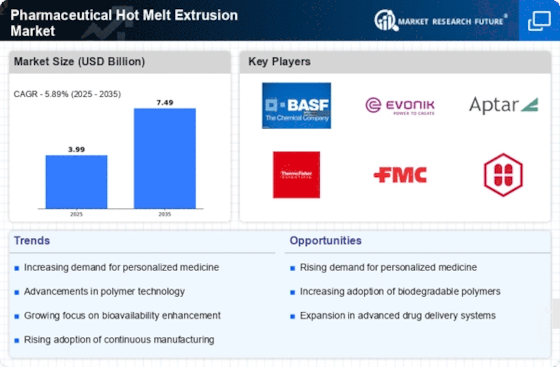

Rising Demand for Advanced Drug Delivery Systems

The Pharmaceutical Hot Melt Extrusion Market is experiencing a notable increase in demand for advanced drug delivery systems. This trend is largely driven by the need for improved bioavailability and controlled release of medications. Hot melt extrusion technology facilitates the development of solid dispersions, which enhance the solubility of poorly water-soluble drugs. According to recent estimates, the market for drug delivery systems is projected to grow at a compound annual growth rate (CAGR) of approximately 7% over the next few years. This growth is indicative of the increasing reliance on innovative technologies to meet patient needs, thereby propelling the Pharmaceutical Hot Melt Extrusion Market forward.