Growth in Automotive Sector

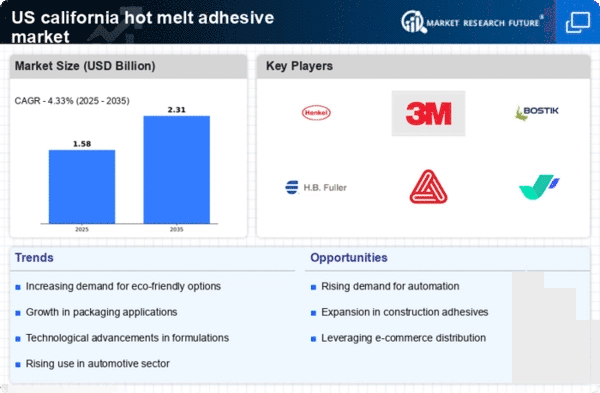

The automotive industry in the United States is undergoing a transformation, which is positively impacting the US Hot Melt Adhesives Market. With the increasing focus on lightweight materials and fuel efficiency, manufacturers are increasingly utilizing hot melt adhesives for bonding various components. These adhesives offer advantages such as reduced weight and enhanced durability, which are critical in modern vehicle design. The automotive sector is expected to witness a growth rate of around 3% annually, leading to a heightened demand for innovative adhesive solutions. Furthermore, the shift towards electric vehicles (EVs) is likely to create new opportunities for hot melt adhesives, as they are essential in assembling battery packs and other components. Consequently, the growth in the automotive sector serves as a significant driver for the US Hot Melt Adhesives Market.

Rising Demand in Packaging Industry

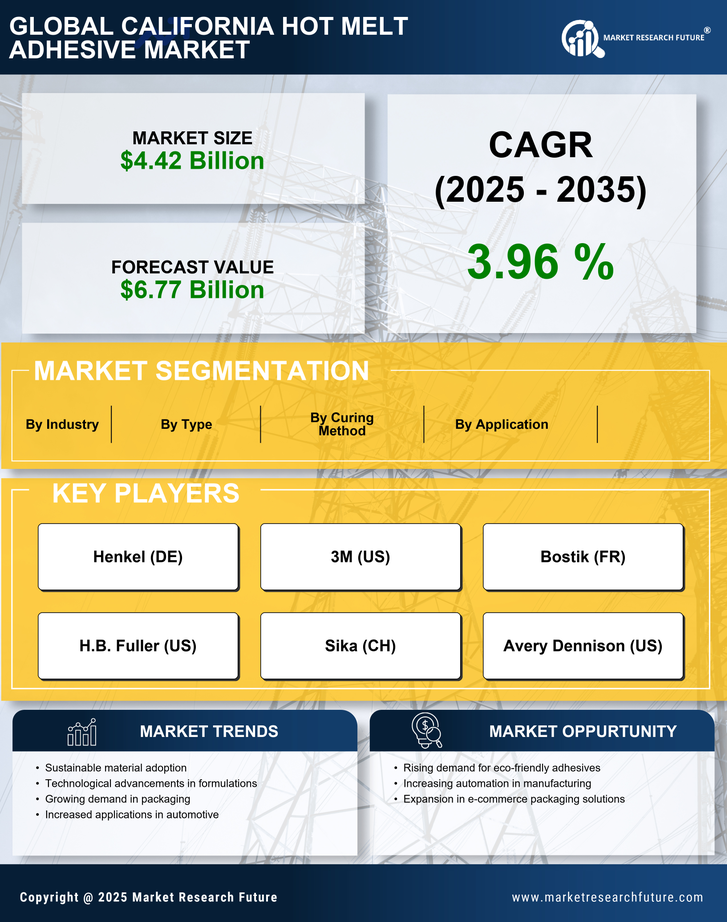

The US Hot Melt Adhesives Market is experiencing a notable surge in demand, particularly from the packaging sector. As e-commerce continues to expand, the need for efficient and reliable packaging solutions has become paramount. Hot melt adhesives are favored for their quick setting times and strong bonding capabilities, making them ideal for various packaging applications. According to recent data, the packaging industry is projected to grow at a compound annual growth rate (CAGR) of approximately 4.5% through 2026, which directly influences the demand for hot melt adhesives. This growth is further fueled by the increasing preference for sustainable packaging solutions, where hot melt adhesives play a crucial role in ensuring product integrity during transit. Thus, the rising demand in the packaging industry significantly propels the US Hot Melt Adhesives Market.

Expansion of Construction Activities

The construction industry in the United States is witnessing a resurgence, which is positively impacting the US Hot Melt Adhesives Market. With the rise in residential and commercial construction projects, there is an increasing need for effective bonding solutions. Hot melt adhesives are utilized in various applications, including flooring, roofing, and insulation, due to their strong adhesion properties and ease of application. The construction sector is projected to grow at a rate of approximately 5% annually, driven by infrastructure development and urbanization. This expansion creates a favorable environment for hot melt adhesive manufacturers, as they seek to provide solutions that meet the evolving needs of the construction industry. Consequently, the expansion of construction activities serves as a vital driver for the US Hot Melt Adhesives Market.

Increased Focus on Sustainable Practices

Sustainability has become a central theme in various industries, including the US Hot Melt Adhesives Market. Companies are increasingly adopting eco-friendly practices, which include the use of sustainable adhesive solutions. Hot melt adhesives, particularly those derived from renewable resources, are gaining popularity as they reduce environmental impact. The US government has implemented various policies aimed at promoting sustainability, which encourages manufacturers to adopt greener practices. This shift towards sustainability is not only beneficial for the environment but also appeals to consumers who are becoming more environmentally conscious. As a result, the increased focus on sustainable practices is likely to drive demand for hot melt adhesives that meet these criteria, thereby influencing the growth trajectory of the US Hot Melt Adhesives Market.

Technological Innovations in Adhesive Formulations

Technological advancements in adhesive formulations are playing a pivotal role in shaping the US Hot Melt Adhesives Market. Manufacturers are increasingly investing in research and development to create high-performance adhesives that cater to specific applications. Innovations such as the development of low-temperature hot melt adhesives and bio-based formulations are gaining traction. These advancements not only enhance the performance of adhesives but also align with sustainability goals, appealing to environmentally conscious consumers. The introduction of smart adhesives, which can respond to environmental changes, is also on the rise. As a result, the continuous evolution of adhesive technologies is likely to drive growth in the US Hot Melt Adhesives Market, as companies seek to improve product performance and meet diverse customer needs.