Cost Efficiency

The Panelized Modular Building System Market is increasingly recognized for its cost efficiency. By utilizing prefabricated components, construction time is significantly reduced, leading to lower labor costs. According to recent data, projects utilizing panelized modular systems can be completed up to 50% faster than traditional construction methods. This rapid assembly not only minimizes labor expenses but also reduces overhead costs associated with prolonged project timelines. Furthermore, the ability to control material waste during the manufacturing process contributes to overall cost savings. As developers and contractors seek to optimize budgets, the appeal of panelized modular systems continues to grow, making them a preferred choice in various construction projects.

Technological Integration

Technological integration plays a significant role in the evolution of the Panelized Modular Building System Market. Advancements in construction technology, such as Building Information Modeling (BIM) and automation, enhance the efficiency and accuracy of modular construction. These technologies facilitate better planning, design, and execution of projects, reducing errors and improving overall quality. Data indicates that the use of BIM in modular construction can lead to a reduction in project delays by up to 30%. As technology continues to advance, the panelized modular approach is likely to become even more streamlined, attracting more stakeholders in the construction industry who seek innovative solutions.

Flexibility and Customization

Flexibility and customization are pivotal drivers in the Panelized Modular Building System Market. These systems allow for a high degree of design adaptability, enabling architects and builders to tailor structures to specific client needs. The modular approach facilitates easy modifications, whether for residential, commercial, or industrial applications. This adaptability is particularly advantageous in urban settings where space constraints often necessitate innovative design solutions. Market data indicates that projects employing modular systems can accommodate changes in design with minimal disruption, thus appealing to a broader range of clients. As the demand for personalized spaces increases, the flexibility offered by panelized modular systems positions them as a leading option in the construction sector.

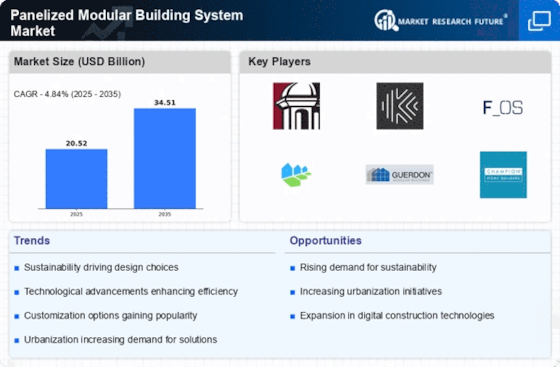

Urbanization and Housing Demand

Urbanization is a driving force in the Panelized Modular Building System Market, as increasing populations in urban areas create a pressing need for housing solutions. The rapid growth of cities has led to a surge in demand for efficient and timely construction methods. Panelized modular systems offer a viable solution to address this housing crisis, providing quick and scalable options for residential developments. Market analysis shows that urban areas are increasingly adopting modular construction to meet housing demands, with some regions reporting a 20% increase in modular housing projects over the past year. This trend suggests that as urbanization continues, the panelized modular building approach will play a crucial role in shaping future housing landscapes.

Sustainability and Environmental Impact

Sustainability is a crucial consideration in the Panelized Modular Building System Market. These systems are designed to minimize environmental impact through efficient use of materials and energy. The manufacturing process often incorporates sustainable practices, such as using recycled materials and reducing waste. Additionally, panelized modular buildings can be designed for energy efficiency, potentially lowering operational costs for occupants. Recent studies suggest that buildings constructed with modular techniques can achieve higher energy performance ratings compared to traditional structures. As environmental regulations become more stringent, the emphasis on sustainable construction practices is likely to drive further adoption of panelized modular systems.