Labor Shortages and Skill Gaps

The Painting Robot Market is significantly influenced by the ongoing labor shortages and skill gaps in various manufacturing sectors. As industries face challenges in sourcing skilled labor for manual painting tasks, the adoption of painting robots presents a viable solution. The need for skilled painters is projected to decline, with many companies turning to automation to fill the void. This shift not only addresses labor shortages but also allows for consistent quality and faster production times. The Painting Robot Market is likely to see increased investments as companies prioritize robotic solutions to mitigate the impact of labor challenges. Furthermore, the integration of painting robots can lead to safer working environments, reducing the risk of workplace injuries associated with manual painting.

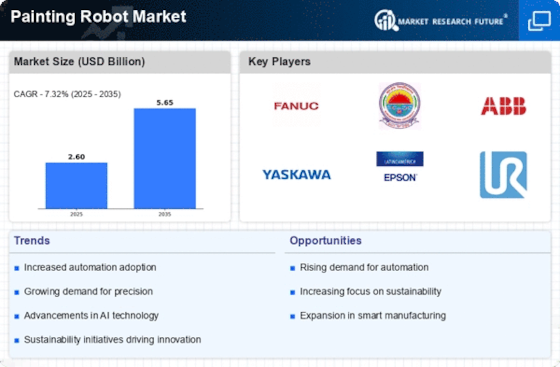

Increased Demand for Automation

The Painting Robot Market is experiencing a notable surge in demand for automation across various sectors. Industries such as automotive, aerospace, and construction are increasingly adopting robotic solutions to enhance efficiency and reduce labor costs. According to recent data, the market for industrial robots is projected to grow at a compound annual growth rate of approximately 10% over the next five years. This trend indicates a shift towards automated painting processes, which not only improve precision but also minimize human error. As companies strive to optimize production lines, the integration of painting robots becomes a strategic imperative. The Painting Robot Market is thus positioned to benefit from this growing inclination towards automation, as businesses seek to streamline operations and enhance overall productivity.

Rising Focus on Quality and Consistency

Quality and consistency are paramount in the Painting Robot Market, as manufacturers strive to meet stringent quality standards. The precision offered by painting robots ensures uniform application of coatings, which is crucial in industries such as automotive and electronics. Recent studies indicate that companies utilizing robotic painting solutions report a significant reduction in defects and rework, leading to cost savings and enhanced customer satisfaction. As consumers demand higher quality products, the Painting Robot Market is likely to expand, driven by the need for reliable and consistent painting processes. This focus on quality not only enhances brand reputation but also positions companies competitively in the marketplace, further fueling the adoption of robotic painting technologies.

Technological Innovations and Advancements

Technological innovations are reshaping the Painting Robot Market, with advancements in artificial intelligence, machine learning, and sensor technologies driving the evolution of robotic painting solutions. These innovations enable robots to adapt to various surfaces and materials, enhancing their versatility and application range. The integration of smart technologies allows for real-time monitoring and adjustments, ensuring optimal performance and efficiency. As manufacturers seek to leverage these advancements, the Painting Robot Market is poised for growth. The increasing complexity of modern manufacturing processes necessitates the adoption of advanced robotic solutions, which can provide the agility and precision required in today's competitive landscape. This trend suggests a promising future for the Painting Robot Market as it embraces cutting-edge technologies.

Environmental Regulations and Sustainability Initiatives

The Painting Robot Market is increasingly influenced by stringent environmental regulations and sustainability initiatives. As governments and organizations prioritize eco-friendly practices, the demand for low-emission and efficient painting processes is on the rise. Painting robots, which often utilize advanced technologies to minimize waste and reduce volatile organic compounds, align with these sustainability goals. The market is witnessing a shift towards water-based and environmentally friendly coatings, further driving the adoption of robotic solutions. Companies that invest in painting robots not only comply with regulations but also enhance their corporate social responsibility profiles. This alignment with sustainability trends positions the Painting Robot Market favorably, as businesses seek to improve their environmental impact while maintaining operational efficiency.