Technological Advancements

Technological advancements play a pivotal role in shaping the Paint Process Automation Market. Innovations in robotics, artificial intelligence, and machine learning are revolutionizing the way paint processes are automated. These technologies enable more precise application, improved quality control, and reduced waste. For instance, the integration of AI-driven systems allows for real-time monitoring and adjustments during the painting process, enhancing overall efficiency. The market for industrial robots, which are increasingly utilized in paint applications, is expected to reach USD 70 billion by 2025. Such advancements not only improve operational efficiency but also contribute to the sustainability goals of manufacturers, making the Paint Process Automation Market a focal point for future investments.

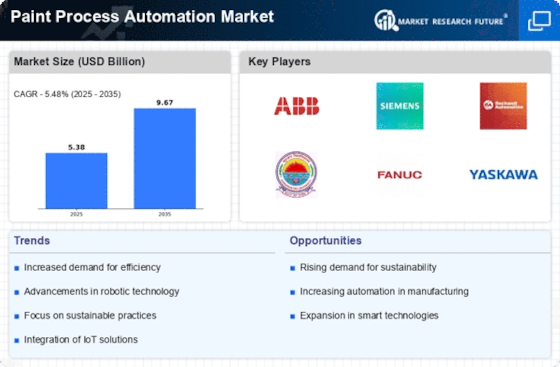

Increased Demand for Automation

The Paint Process Automation Market is experiencing a surge in demand for automation solutions. This trend is driven by the need for enhanced efficiency and productivity in manufacturing processes. Companies are increasingly adopting automated systems to streamline operations, reduce labor costs, and minimize human error. According to recent data, the automation market is projected to grow at a compound annual growth rate of approximately 10% over the next five years. This growth is indicative of a broader shift towards automation across various sectors, including automotive and consumer goods, where paint application processes are critical. As manufacturers seek to optimize their production lines, the Paint Process Automation Market stands to benefit significantly from this trend.

Focus on Quality and Consistency

Quality and consistency are paramount in the Paint Process Automation Market. As consumer expectations rise, manufacturers are compelled to adopt automated solutions that ensure uniformity in paint application. Automated systems provide precise control over variables such as paint thickness and drying times, which are crucial for achieving high-quality finishes. This focus on quality is reflected in the increasing adoption of automated paint booths and robotic arms, which enhance the precision of the painting process. Market analysis indicates that companies prioritizing quality through automation are likely to see a 15% increase in customer satisfaction and retention. Thus, the emphasis on quality and consistency is a significant driver for the Paint Process Automation Market.

Cost Reduction and Operational Efficiency

Cost reduction and operational efficiency are central to the Paint Process Automation Market. Manufacturers are increasingly recognizing that automation can lead to substantial cost savings by optimizing resource utilization and reducing waste. Automated paint processes minimize material costs through precise application techniques, which can reduce overspray and excess usage. Furthermore, the implementation of automated systems can decrease labor costs by streamlining workflows and reducing the need for manual intervention. Market studies suggest that companies that invest in automation can achieve operational cost reductions of up to 30%. This potential for cost efficiency is a compelling driver for the Paint Process Automation Market, as businesses strive to enhance their competitive edge.

Regulatory Compliance and Safety Standards

Regulatory compliance and safety standards are critical drivers in the Paint Process Automation Market. As environmental regulations become more stringent, manufacturers are compelled to adopt automated solutions that minimize hazardous emissions and ensure worker safety. Automation technologies facilitate compliance with regulations by providing accurate monitoring and reporting capabilities. For example, automated systems can track VOC emissions in real-time, helping companies adhere to environmental standards. The market for compliance-related automation solutions is projected to grow as industries seek to mitigate risks associated with non-compliance. Consequently, the need for regulatory adherence is likely to propel the growth of the Paint Process Automation Market.