Regulatory Compliance

Regulatory compliance is increasingly influencing the Oil and Gas Hose Assemblies Market. Governments and regulatory bodies are implementing stringent safety and environmental regulations to mitigate risks associated with oil and gas operations. Compliance with these regulations often necessitates the use of high-performance hose assemblies that can withstand extreme conditions and prevent leaks. As of 2025, it is anticipated that the regulatory landscape will become even more complex, compelling companies to invest in advanced hose technologies. This trend not only drives demand for innovative products but also encourages manufacturers to enhance their offerings to meet compliance standards.

Rising Demand for Energy

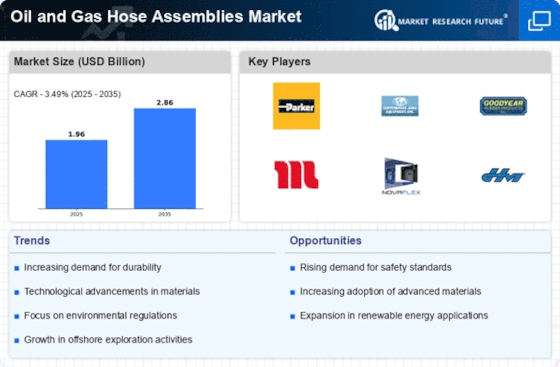

The increasing The Oil and Gas Hose Assemblies Industry. As economies expand and populations grow, the need for efficient energy sources intensifies. This demand propels investments in oil and gas exploration and production, subsequently increasing the requirement for robust hose assemblies. In 2025, the energy sector is projected to witness a compound annual growth rate of approximately 4.5%, further emphasizing the necessity for high-quality hose assemblies that can withstand the rigors of extraction and transportation processes. The Oil and Gas Hose Assemblies Market must adapt to these evolving demands to ensure reliability and safety in energy supply.

Technological Innovations

Technological innovations are reshaping the Oil and Gas Hose Assemblies Market. Advancements in materials science and engineering have led to the development of hoses that are lighter, more flexible, and resistant to harsh environmental conditions. These innovations enable operators to enhance efficiency and safety in oil and gas operations. In 2025, the market is expected to see a rise in the adoption of smart hose technologies, which incorporate sensors to monitor performance and detect potential failures. Such innovations not only improve operational reliability but also contribute to cost savings, making them attractive to industry stakeholders.

Infrastructure Development

Infrastructure development plays a crucial role in shaping the Oil and Gas Hose Assemblies Market. As countries invest in enhancing their energy infrastructure, the need for durable and efficient hose assemblies becomes paramount. New pipelines, refineries, and storage facilities require specialized hose solutions to facilitate the safe transport of oil and gas. In recent years, investments in infrastructure have surged, with estimates suggesting that the sector could reach a valuation of over 3 trillion dollars by 2026. This growth necessitates the continuous evolution of hose assembly technologies to meet the rigorous standards of modern infrastructure projects.

Increased Exploration Activities

Increased exploration activities are a significant driver of the Oil and Gas Hose Assemblies Market. As companies seek to discover new reserves, particularly in challenging environments such as deepwater and Arctic regions, the demand for specialized hose assemblies rises. These environments require hoses that can endure extreme pressures and temperatures, thus driving innovation in design and materials. The exploration sector is projected to grow steadily, with investments expected to exceed 200 billion dollars by 2026. This growth underscores the necessity for high-quality hose assemblies that can support the rigorous demands of modern exploration efforts.