Expansion of Industrial Applications

The expansion of industrial applications is a key driver for the Oil Condition Monitoring Market. Various sectors, including automotive, aerospace, and manufacturing, are increasingly recognizing the benefits of oil condition monitoring. The ability to monitor oil conditions in real-time allows for proactive maintenance strategies, which can lead to improved equipment reliability and reduced operational costs. As industries continue to evolve and adopt advanced technologies, the demand for oil condition monitoring solutions is likely to grow. This trend indicates a robust future for the market as more sectors integrate these monitoring practices into their operations.

Rising Awareness of Environmental Impact

There is a growing awareness of the environmental impact associated with oil usage, which is influencing the Oil Condition Monitoring Market. Companies are increasingly adopting oil condition monitoring practices to minimize waste and reduce their carbon footprint. By ensuring optimal oil conditions, organizations can extend the life of their lubricants and decrease the frequency of oil disposal. This not only aligns with sustainability goals but also enhances corporate responsibility. As environmental concerns continue to rise, the demand for oil condition monitoring solutions is expected to increase, fostering market growth.

Increasing Demand for Efficient Operations

The Oil Condition Monitoring Market is experiencing a surge in demand for efficient operational practices. Companies are increasingly recognizing the importance of maintaining optimal oil conditions to enhance machinery performance and reduce downtime. This trend is driven by the need to minimize operational costs and maximize productivity. According to recent data, organizations that implement oil condition monitoring can achieve up to a 30% reduction in maintenance costs. As industries strive for operational excellence, the adoption of oil condition monitoring technologies is likely to become a standard practice, further propelling market growth.

Regulatory Compliance and Safety Standards

The Oil Condition Monitoring Market is significantly influenced by stringent regulatory compliance and safety standards. Governments and regulatory bodies are imposing regulations that mandate regular monitoring of oil conditions to ensure environmental safety and equipment reliability. This has led to an increased adoption of oil condition monitoring systems across various sectors, including manufacturing and transportation. Companies that fail to comply with these regulations may face hefty fines and operational disruptions. Consequently, the need for reliable monitoring solutions is becoming more pronounced, driving market expansion.

Technological Advancements in Monitoring Solutions

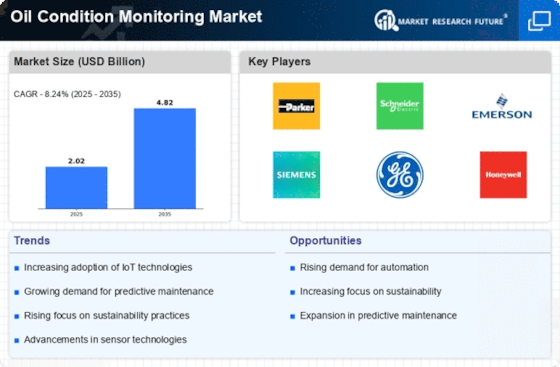

Technological advancements are playing a pivotal role in the Oil Condition Monitoring Market. Innovations such as real-time monitoring systems and advanced data analytics are enhancing the accuracy and reliability of oil condition assessments. These technologies enable companies to detect potential issues before they escalate, thereby reducing the risk of equipment failure. The market for oil condition monitoring solutions is projected to grow at a compound annual growth rate of approximately 8% over the next five years. As organizations increasingly invest in cutting-edge monitoring solutions, the industry is poised for substantial growth.