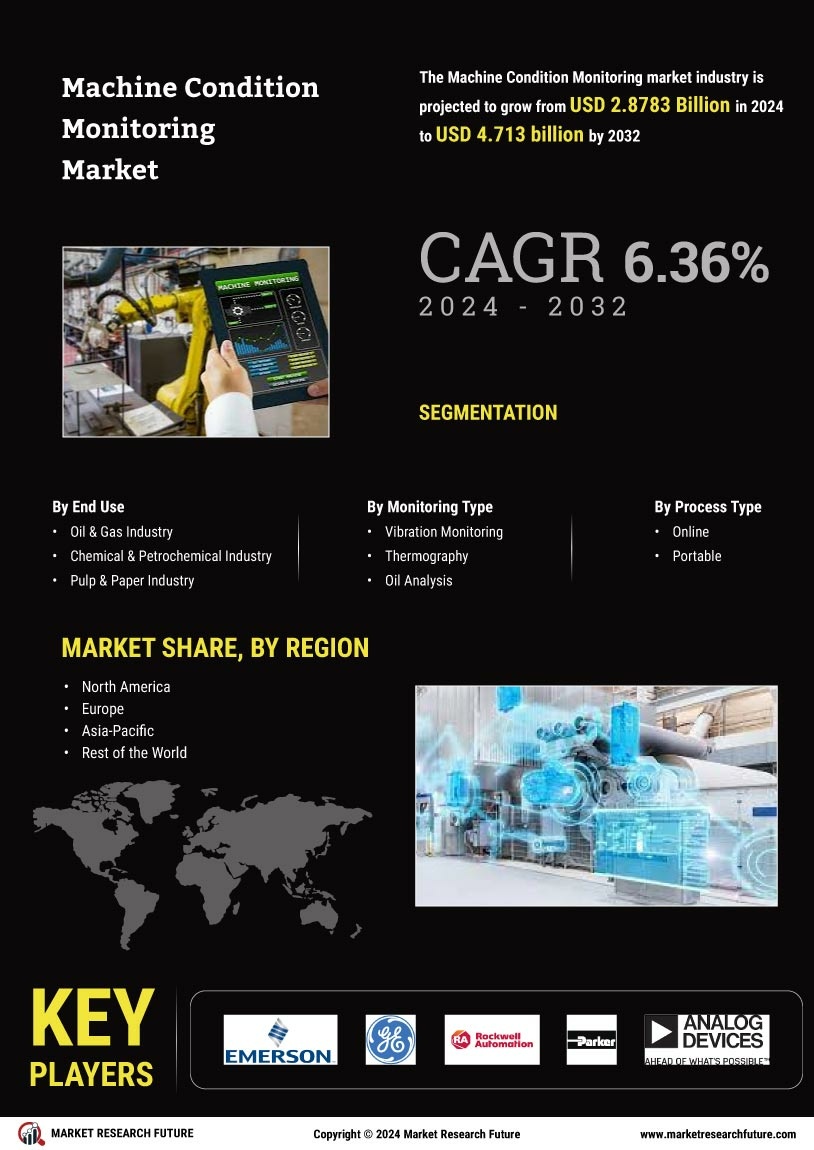

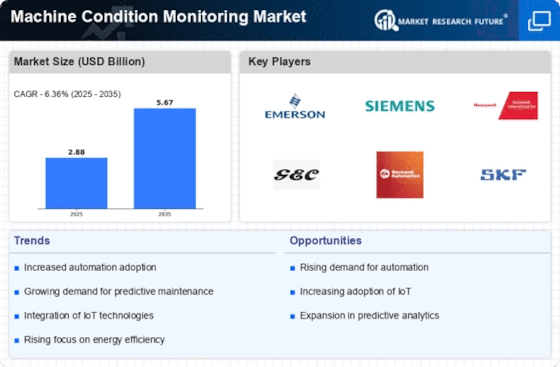

Rising Demand for Automation

The Machine Condition Monitoring Market is experiencing a notable surge in demand for automation across various sectors. Industries are increasingly adopting automated systems to enhance operational efficiency and reduce human error. This trend is particularly evident in manufacturing, where the integration of machine condition monitoring technologies allows for real-time data collection and analysis. According to recent estimates, the automation market is projected to grow at a compound annual growth rate of approximately 9% over the next five years. This growth is likely to drive the adoption of machine condition monitoring solutions, as companies seek to optimize their processes and minimize downtime. As a result, the Machine Condition Monitoring Market is poised to benefit significantly from this shift towards automation.

Growing Emphasis on Safety and Compliance

The Machine Condition Monitoring Market is increasingly shaped by the growing emphasis on safety and regulatory compliance. Industries are under pressure to adhere to stringent safety standards and regulations, which necessitate the implementation of effective monitoring systems. Machine condition monitoring plays a crucial role in ensuring that equipment operates within safe parameters, thereby minimizing the risk of accidents and injuries. Recent studies suggest that companies that prioritize safety through condition monitoring can reduce workplace incidents by up to 40%. This heightened focus on safety is likely to drive the adoption of machine condition monitoring solutions, as organizations seek to mitigate risks and comply with regulatory requirements. As a result, the Machine Condition Monitoring Market is expected to see sustained growth in response to these safety and compliance demands.

Increasing Focus on Predictive Maintenance

The Machine Condition Monitoring Market is witnessing a paradigm shift towards predictive maintenance strategies. Organizations are increasingly recognizing the value of monitoring equipment conditions to predict failures before they occur. This proactive approach not only reduces maintenance costs but also enhances equipment lifespan. Recent data indicates that predictive maintenance can lead to a reduction in maintenance costs by up to 30%. As industries strive for operational excellence, the demand for machine condition monitoring solutions that facilitate predictive maintenance is expected to rise. This trend is particularly pronounced in sectors such as manufacturing and energy, where unplanned downtime can result in substantial financial losses. Consequently, the Machine Condition Monitoring Market is likely to expand as businesses invest in technologies that support predictive maintenance initiatives.

Expansion of Industrial Internet of Things (IIoT)

The Machine Condition Monitoring Market is being propelled by the expansion of the Industrial Internet of Things (IIoT). The integration of IIoT technologies into manufacturing processes allows for enhanced connectivity and data exchange between machines and systems. This interconnectedness facilitates more effective monitoring and analysis of machine conditions, leading to improved operational efficiency. The IIoT market is anticipated to grow at a compound annual growth rate of around 10%, which will likely have a positive impact on the Machine Condition Monitoring Market. As industries increasingly adopt IIoT solutions, the demand for machine condition monitoring technologies that leverage this connectivity is expected to rise. This trend underscores the importance of real-time data in optimizing maintenance strategies and enhancing overall productivity.

Technological Advancements in Sensor Technologies

The Machine Condition Monitoring Market is significantly influenced by advancements in sensor technologies. The development of more sophisticated sensors enables the collection of precise data regarding machine performance and health. Innovations such as wireless sensors and IoT-enabled devices are transforming the landscape of machine condition monitoring. These technologies facilitate real-time monitoring and data transmission, allowing for timely interventions. The market for sensors is projected to grow at a rate of approximately 8% annually, which will likely bolster the Machine Condition Monitoring Market. As industries adopt these advanced sensor technologies, the ability to monitor equipment conditions in real-time will enhance decision-making processes and improve overall operational efficiency.