Increased Focus on Safety Standards

Safety regulations and standards play a crucial role in shaping the Molded FRP Grating Market. As industries face heightened scrutiny regarding workplace safety, the demand for materials that comply with stringent safety standards is on the rise. Molded FRP grating offers slip resistance and fire retardant properties, making it a preferred choice for environments where safety is paramount. The market is expected to expand as more companies recognize the importance of adhering to safety regulations, which could lead to increased investments in molded FRP solutions. Additionally, the integration of molded FRP grating in safety-critical applications, such as walkways and platforms, further underscores its relevance in the market. This focus on safety not only enhances operational integrity but also positions the Molded FRP Grating Market as a key player in promoting safer work environments.

Rising Demand in Industrial Applications

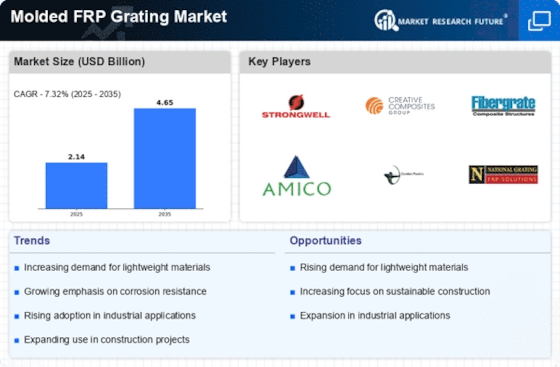

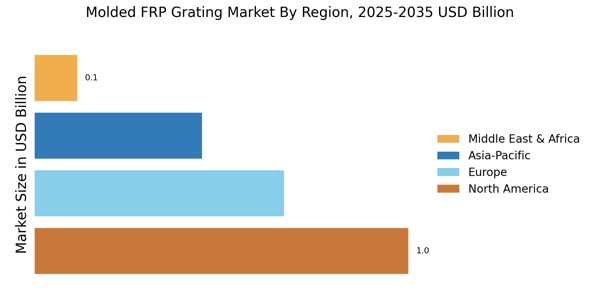

The Molded FRP Grating Market experiences a notable surge in demand driven by its extensive applications in various industrial sectors. Industries such as oil and gas, chemical processing, and wastewater treatment increasingly adopt molded fiberglass reinforced plastic grating due to its corrosion resistance and lightweight properties. The market is projected to grow at a compound annual growth rate (CAGR) of approximately 5% over the next few years, reflecting the industry's shift towards materials that enhance safety and efficiency. Furthermore, the durability of molded FRP grating reduces maintenance costs, making it an attractive option for industries seeking long-term solutions. As companies prioritize operational efficiency, the Molded FRP Grating Market is likely to witness sustained growth, aligning with the broader trends of industrial modernization and infrastructure development.

Technological Innovations in Manufacturing

Technological advancements are reshaping the Molded FRP Grating Market, leading to improved manufacturing processes and product quality. Innovations such as automated production techniques and advanced resin formulations enhance the performance characteristics of molded FRP grating, making it more durable and versatile. These technological improvements are likely to result in a broader range of applications, from construction to marine environments. As manufacturers invest in research and development, the market may witness the introduction of new products that cater to specific industry needs. This focus on innovation not only boosts the competitiveness of the Molded FRP Grating Market but also aligns with the growing demand for high-performance materials in various sectors.

Growing Infrastructure Development Projects

Infrastructure development projects are a significant driver for the Molded FRP Grating Market, as urbanization and population growth necessitate the construction of new facilities and upgrades to existing ones. Molded FRP grating is increasingly utilized in public infrastructure, including bridges, walkways, and drainage systems, due to its lightweight and corrosion-resistant properties. The market is poised for growth as governments and private entities invest in infrastructure to support economic development. Additionally, the durability and low maintenance requirements of molded FRP grating make it an appealing choice for long-term infrastructure solutions. As the demand for robust and sustainable infrastructure continues to rise, the Molded FRP Grating Market is likely to benefit from these ongoing projects.

Sustainability and Environmental Considerations

The Molded FRP Grating Market is increasingly influenced by sustainability initiatives as companies strive to reduce their environmental footprint. Molded fiberglass reinforced plastic grating is often manufactured using eco-friendly processes, which appeals to organizations committed to sustainability. The lightweight nature of molded FRP grating also contributes to lower transportation emissions, aligning with global efforts to minimize carbon footprints. As industries adopt greener practices, the demand for sustainable materials is expected to rise, potentially driving growth in the molded FRP grating sector. Furthermore, the recyclability of FRP materials enhances their appeal in environmentally conscious markets. This trend towards sustainability not only reflects changing consumer preferences but also positions the Molded FRP Grating Market favorably in a landscape increasingly focused on environmental responsibility.