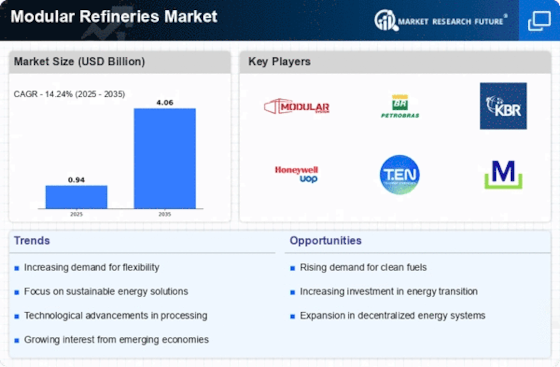

The Modular Refineries Market is currently characterized by a dynamic competitive landscape, driven by the increasing demand for localized refining solutions and the need for energy security. Key players such as Modular Refining Systems (US), Petrobras (BR), and Honeywell UOP (US) are strategically positioning themselves to capitalize on these trends. Modular Refining Systems (US) focuses on innovative modular designs that allow for rapid deployment and scalability, catering to smaller markets and emerging economies. Petrobras (BR) emphasizes regional expansion and sustainability, aligning its operations with Brazil's energy transition goals. Meanwhile, Honeywell UOP (US) leverages its technological expertise to enhance operational efficiencies and reduce environmental impact, thereby shaping a competitive environment that prioritizes innovation and sustainability.

In terms of business tactics, companies are increasingly localizing manufacturing and optimizing supply chains to enhance responsiveness to market demands. The Modular Refineries Market appears moderately fragmented, with a mix of established players and new entrants vying for market share. The collective influence of these key players fosters a competitive structure that encourages innovation and collaboration, as companies seek to differentiate themselves through advanced technologies and sustainable practices.

In August 2025, Modular Refining Systems (US) announced a partnership with a local energy firm in Southeast Asia to establish a new modular refinery, aimed at addressing the region's growing fuel demand. This strategic move not only enhances Modular Refining Systems' market presence but also underscores the importance of localized solutions in meeting specific regional needs. The partnership is expected to facilitate knowledge transfer and technology sharing, further solidifying the company's competitive edge.

In September 2025, Petrobras (BR) unveiled its latest sustainability initiative, which includes the integration of biofuels into its modular refinery operations. This initiative is pivotal as it aligns with Brazil's commitment to reducing carbon emissions and diversifying its energy portfolio. By incorporating biofuels, Petrobras not only enhances its product offerings but also positions itself as a leader in sustainable refining practices, potentially attracting environmentally conscious investors and customers.

In October 2025, Honeywell UOP (US) launched a new digital platform designed to optimize refinery operations through advanced analytics and AI integration. This platform aims to improve decision-making processes and operational efficiencies, reflecting a broader trend towards digitalization in the industry. By investing in such technologies, Honeywell UOP is likely to enhance its competitive positioning, enabling clients to achieve greater operational reliability and cost-effectiveness.

As of October 2025, the Modular Refineries Market is witnessing a shift towards digitalization, sustainability, and AI integration, which are defining current competitive trends. Strategic alliances are increasingly shaping the landscape, as companies recognize the value of collaboration in driving innovation and enhancing market responsiveness. Looking ahead, competitive differentiation is expected to evolve, with a pronounced shift from price-based competition to a focus on technological advancements, innovation, and supply chain reliability. This transition may redefine how companies engage with their customers and stakeholders, ultimately shaping the future of the Modular Refineries Market.