Regulatory Support for Prefabrication

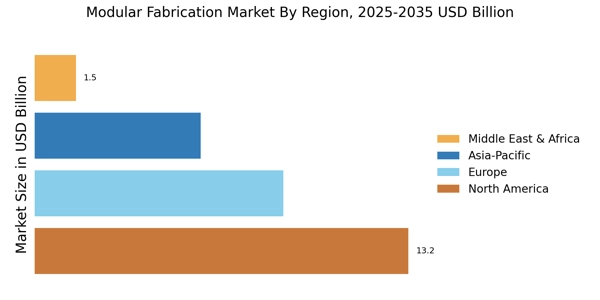

Regulatory frameworks are increasingly supportive of prefabrication methods, which is advantageous for the Modular Fabrication Market. Governments are recognizing the benefits of modular construction in terms of efficiency, safety, and cost-effectiveness. Incentives and policies promoting offsite construction are being implemented in various regions, encouraging investment in modular technologies. For instance, certain jurisdictions offer tax breaks or expedited permitting processes for projects utilizing modular techniques. This regulatory support is expected to enhance the attractiveness of modular solutions, potentially leading to a market expansion. As more stakeholders become aware of these benefits, the Modular Fabrication Market is poised for growth.

Growing Emphasis on Sustainable Practices

Sustainability has become a pivotal focus within the Modular Fabrication Market. As environmental concerns escalate, construction companies are increasingly adopting sustainable practices to minimize their carbon footprint. Modular fabrication techniques often utilize eco-friendly materials and generate less waste compared to traditional construction methods. Recent studies indicate that the market for sustainable building materials is expected to reach USD 500 billion by 2027. This shift towards sustainability not only aligns with regulatory requirements but also appeals to environmentally conscious consumers. Consequently, the Modular Fabrication Market is likely to see a rise in demand for sustainable solutions, driving innovation and growth.

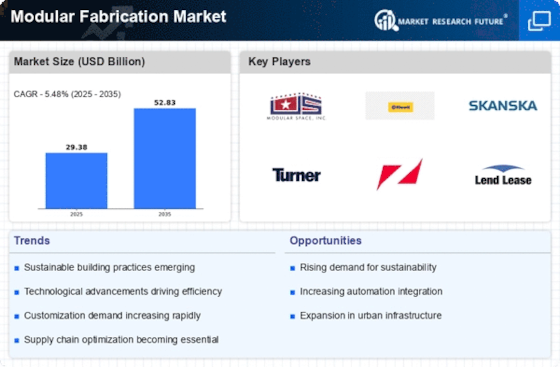

Increased Demand for Offsite Construction

The Modular Fabrication Market experiences a notable surge in demand for offsite construction methods. This trend is driven by the need for faster project completion times and reduced labor costs. Offsite construction allows for components to be manufactured in a controlled environment, minimizing delays caused by weather or site conditions. According to recent data, the offsite construction market is projected to grow at a compound annual growth rate of approximately 6.5% over the next few years. This growth is indicative of a broader shift towards efficiency and productivity in construction practices, which is likely to bolster the Modular Fabrication Market as stakeholders seek innovative solutions to meet project timelines.

Rising Urbanization and Infrastructure Development

The ongoing trend of urbanization is significantly impacting the Modular Fabrication Market. As populations in urban areas continue to swell, there is an increasing demand for housing and infrastructure. Modular construction offers a viable solution to address these needs efficiently. Recent projections suggest that urban areas will account for nearly 70% of the global population by 2050, necessitating innovative construction methods. Modular fabrication allows for rapid deployment of residential and commercial structures, making it an attractive option for developers. This rising urbanization trend is likely to drive the Modular Fabrication Market forward, as stakeholders seek to meet the growing demand for infrastructure.

Advancements in Building Information Modeling (BIM)

The integration of Building Information Modeling (BIM) technology is transforming the Modular Fabrication Market. BIM facilitates enhanced collaboration among architects, engineers, and contractors, leading to improved design accuracy and project management. The adoption of BIM is expected to increase by over 20% in the coming years, as it allows for real-time updates and modifications during the construction process. This technological advancement not only streamlines workflows but also reduces errors and rework, which can be costly. As the construction sector increasingly embraces digital tools, the Modular Fabrication Market stands to benefit from the efficiencies and cost savings that BIM provides.