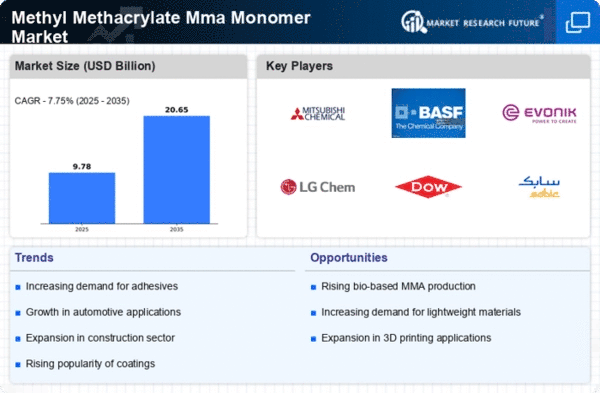

North America : Established Market with Growth Potential

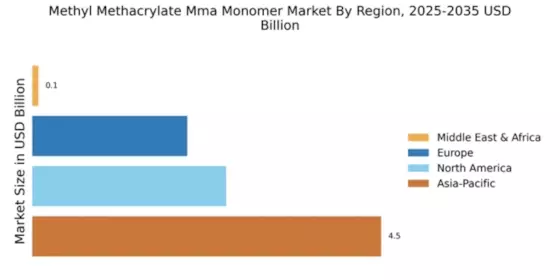

The North American Methyl Methacrylate (MMA) market is projected to grow steadily, driven by increasing demand in the automotive and construction sectors. With a market size of $2.5 billion, the region benefits from a robust regulatory framework that encourages innovation and sustainability. The push for eco-friendly materials is also a significant catalyst, as manufacturers seek to reduce their carbon footprint and comply with stringent environmental regulations.

Leading countries such as the US and Canada are home to major players like Dow Inc. and Hexion Inc., which are investing in advanced production technologies. The competitive landscape is characterized by strategic partnerships and collaborations aimed at enhancing product offerings. As the market evolves, the presence of key players will continue to shape the dynamics, ensuring North America remains a vital player in the global MMA landscape.

Europe : Innovation and Sustainability Focus

Europe's Methyl Methacrylate market, valued at $2.0 billion, is witnessing growth fueled by innovation and sustainability initiatives. The region is increasingly adopting MMA in applications such as coatings and adhesives, driven by regulatory support for eco-friendly products. The European market is characterized by a strong emphasis on reducing emissions and enhancing product performance, aligning with the EU's Green Deal objectives.

Germany, France, and the UK are leading countries in this market, hosting key players like BASF SE and Arkema S.A. The competitive landscape is marked by significant R&D investments aimed at developing sustainable MMA solutions. As the market matures, collaboration among industry stakeholders will be crucial for maintaining competitiveness and meeting evolving consumer demands. "The European market is committed to sustainability and innovation, driving the growth of Methyl Methacrylate applications," European Chemical Agency.

Asia-Pacific : Emerging Powerhouse in MMA Production

Asia-Pacific is the largest market for Methyl Methacrylate, with a market size of $4.5 billion, driven by rapid industrialization and urbanization. The region's growth is supported by increasing demand from the automotive, electronics, and construction sectors. Regulatory frameworks are evolving to promote sustainable practices, further enhancing market dynamics and attracting investments in production technologies.

Countries like China, Japan, and South Korea are at the forefront, with major players such as Mitsubishi Chemical Corporation and LG Chem Ltd. leading the charge. The competitive landscape is characterized by aggressive expansion strategies and technological advancements. As the region continues to grow, the presence of these key players will be instrumental in shaping the future of the MMA market in Asia-Pacific.

Middle East and Africa : Emerging Market with Growth Opportunities

The Middle East and Africa (MEA) Methyl Methacrylate market, valued at $0.08 billion, is in its nascent stages but shows promising growth potential. The region is witnessing increased investments in infrastructure and construction, which are key drivers for MMA demand. Regulatory frameworks are gradually evolving to support industrial growth, creating a conducive environment for market expansion.

Countries like South Africa and the UAE are emerging as key players in the MMA landscape, with local manufacturers beginning to establish their presence. The competitive landscape is still developing, but opportunities for growth are abundant as global players look to tap into the region's potential. As the market matures, the focus will be on building local capabilities and enhancing production efficiency.