Growing Applications in Aerospace

The aerospace sector is emerging as a key driver for the Global Metal Fiber Market Industry, as manufacturers seek materials that can withstand extreme conditions while maintaining lightweight properties. Metal fibers are utilized in various applications, including thermal protection systems and structural components. The increasing focus on fuel efficiency and safety in aviation is likely to bolster demand for metal fibers. As the industry evolves, the market is expected to witness a compound annual growth rate (CAGR) of 9.33% from 2025 to 2035, highlighting the potential for growth within the Global Metal Fiber Market Industry.

Rising Demand in Automotive Sector

The Global Metal Fiber Market Industry experiences a notable surge in demand from the automotive sector, driven by the need for lightweight materials that enhance fuel efficiency. Metal fibers, known for their strength and durability, are increasingly utilized in manufacturing components such as brake pads and exhaust systems. This trend is projected to contribute significantly to the market's growth, with the industry expected to reach 2.63 USD Billion in 2024. As automotive manufacturers seek to comply with stringent emissions regulations, the adoption of metal fibers is likely to expand, indicating a robust future for the Global Metal Fiber Market Industry.

Increased Focus on Energy Efficiency

The Global Metal Fiber Market Industry is significantly influenced by the rising emphasis on energy efficiency across various sectors. Metal fibers are employed in applications such as insulation and filtration, contributing to reduced energy consumption and improved operational efficiency. Industries are increasingly adopting these materials to meet regulatory standards and sustainability goals. This trend is expected to drive the market's expansion, with projections indicating a growth trajectory that could see the industry valued at 2.63 USD Billion in 2024. The shift towards energy-efficient solutions underscores the relevance of metal fibers in contemporary manufacturing.

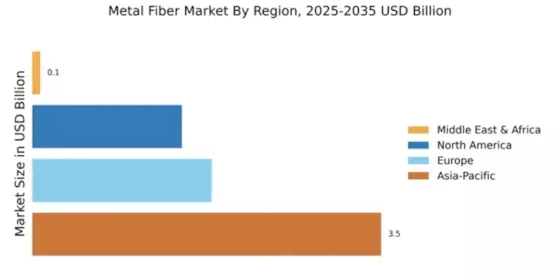

Emerging Markets and Global Expansion

Emerging markets are playing a pivotal role in the growth of the Global Metal Fiber Market Industry. Countries in Asia-Pacific and Latin America are witnessing increased industrialization, leading to heightened demand for metal fibers in various applications. The expansion of manufacturing capabilities in these regions is likely to create new opportunities for market players. As these markets develop, the Global Metal Fiber Market Industry could experience substantial growth, potentially reaching 7.02 USD Billion by 2035. This trend indicates a shift in global manufacturing dynamics, with metal fibers becoming integral to diverse industries.

Advancements in Manufacturing Technologies

Technological innovations in manufacturing processes are propelling the Global Metal Fiber Market Industry forward. Advanced techniques such as 3D printing and laser sintering enable the production of complex geometries and customized metal fiber components. These advancements not only enhance product performance but also reduce waste and production costs. As industries increasingly adopt these technologies, the market is poised for substantial growth, potentially reaching 7.02 USD Billion by 2035. The integration of smart manufacturing practices further indicates a transformative phase for the Global Metal Fiber Market Industry, fostering efficiency and sustainability.