Rising Demand in Defense Sector

The Fiber Reinforced Metal Laminate Market is experiencing a notable surge in demand from the defense sector. This growth is primarily driven by the increasing need for lightweight yet durable materials that can withstand harsh conditions. Military applications require materials that not only provide structural integrity but also enhance fuel efficiency in vehicles and aircraft. The defense sector's focus on advanced materials is expected to propel the Fiber Reinforced Metal Laminate Market, with projections indicating a compound annual growth rate of approximately 6% over the next five years. As nations invest in modernizing their military capabilities, the demand for innovative materials like fiber reinforced metal laminates is likely to rise, further solidifying their role in defense applications.

Growing Interest in Lightweight Materials

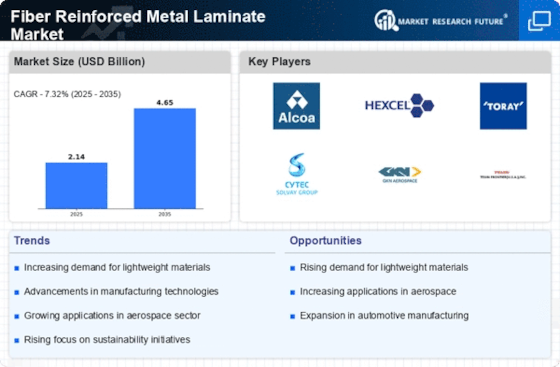

The growing interest in lightweight materials is a pivotal driver for the Fiber Reinforced Metal Laminate Market. Industries such as aerospace and automotive are increasingly prioritizing weight reduction to enhance fuel efficiency and performance. Fiber reinforced metal laminates offer a unique combination of strength and lightweight characteristics, making them an attractive option for manufacturers. The market is expected to grow at a rate of approximately 7% per year as companies seek to meet stringent regulatory standards for emissions and fuel consumption. This trend towards lightweight materials is likely to continue, further boosting the demand for fiber reinforced metal laminates across various sectors.

Regulatory Support for Advanced Materials

Regulatory support for advanced materials is emerging as a key driver for the Fiber Reinforced Metal Laminate Market. Governments are increasingly recognizing the benefits of advanced materials in promoting sustainability and efficiency across various sectors. Policies aimed at reducing carbon emissions and enhancing energy efficiency are encouraging industries to adopt innovative materials like fiber reinforced metal laminates. This regulatory environment is expected to foster growth in the market, with estimates suggesting a potential increase in demand by 5% annually. As regulations evolve, the Fiber Reinforced Metal Laminate Market is likely to benefit from heightened interest and investment in advanced material solutions.

Technological Advancements in Manufacturing

Technological advancements in manufacturing processes are significantly influencing the Fiber Reinforced Metal Laminate Market. Innovations such as automated fiber placement and advanced resin infusion techniques are enhancing the production efficiency and quality of fiber reinforced metal laminates. These advancements allow for the creation of complex geometries and improved material properties, which are essential for various applications, including aerospace and automotive. The market is projected to witness a growth rate of around 5% annually, driven by these technological improvements. As manufacturers adopt cutting-edge technologies, the Fiber Reinforced Metal Laminate Market is likely to expand, catering to the increasing demand for high-performance materials.

Increased Investment in Research and Development

Increased investment in research and development is significantly shaping the Fiber Reinforced Metal Laminate Market. Companies are allocating substantial resources to explore new applications and improve the performance of fiber reinforced metal laminates. This focus on R&D is crucial for developing innovative solutions that meet the evolving needs of industries such as aerospace, automotive, and construction. With a projected annual growth rate of around 6% in R&D spending, the market is poised for expansion as new technologies and applications emerge. This investment not only enhances product offerings but also strengthens the competitive landscape of the Fiber Reinforced Metal Laminate Market.