Expansion of Emerging Markets

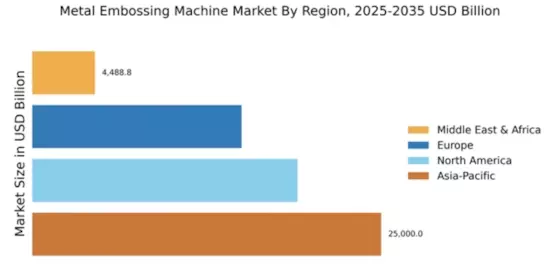

Emerging markets are playing a crucial role in the growth of the Global Metal Embossing Machine Market Industry. Countries in Asia-Pacific and Latin America are witnessing rapid industrialization and urbanization, leading to increased demand for metal products. This trend is further supported by government initiatives aimed at boosting manufacturing capabilities. As these regions develop, the need for efficient and cost-effective metal embossing solutions becomes paramount. The expansion into these markets presents significant opportunities for manufacturers, as they seek to establish a foothold in regions with high growth potential. This geographical diversification is likely to enhance the overall market landscape.

Rising Demand for Customized Products

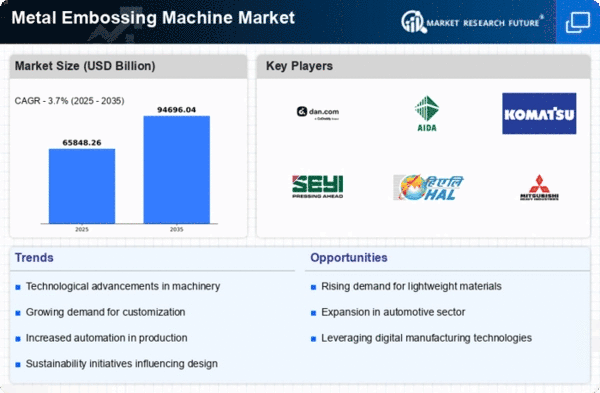

The Global Metal Embossing Machine Market Industry experiences a surge in demand for customized metal products across various sectors, including automotive, aerospace, and consumer goods. This trend is driven by consumers' preferences for personalized designs and unique branding opportunities. Manufacturers are increasingly investing in advanced metal embossing technologies to meet these demands. As a result, the market is projected to grow from 63498.8 USD Billion in 2024 to 112526.5 USD Billion by 2035, indicating a robust growth trajectory. This shift towards customization not only enhances product appeal but also fosters brand loyalty, thereby driving market expansion.

Sustainability and Eco-Friendly Practices

Sustainability has become a critical focus within the Global Metal Embossing Machine Market Industry. Manufacturers are increasingly adopting eco-friendly practices, such as using recyclable materials and reducing energy consumption during production. This shift is driven by both regulatory pressures and consumer preferences for environmentally responsible products. Companies that implement sustainable practices not only enhance their brand image but also reduce operational costs in the long run. As the market evolves, the emphasis on sustainability is expected to influence purchasing decisions, thereby driving demand for advanced metal embossing technologies that align with these eco-friendly initiatives.

Growth in Automotive and Aerospace Sectors

The automotive and aerospace industries are significant contributors to the Global Metal Embossing Machine Market Industry. With the increasing production of vehicles and aircraft, there is a heightened demand for embossed metal components that enhance both aesthetics and functionality. Manufacturers are leveraging metal embossing to create lightweight conveyor belting yet durable parts, which are essential for improving fuel efficiency and performance. The projected growth in these sectors is expected to further stimulate the demand for metal embossing machines, contributing to the overall market expansion. As these industries evolve, they are likely to adopt more sophisticated embossing technologies to meet stringent regulatory standards.

Technological Advancements in Embossing Techniques

Technological innovations play a pivotal role in shaping the Global Metal Embossing Machine Market Industry. The introduction of automated and semi-automated embossing machines enhances production efficiency and precision. These advancements reduce operational costs and minimize waste, making them attractive to manufacturers. Moreover, the integration of digital technologies allows for more intricate designs and faster production cycles. As the industry adapts to these technological changes, the market is expected to witness a compound annual growth rate of 5.34% from 2025 to 2035. This evolution in embossing techniques not only improves product quality but also expands the potential applications of metal embossing.