Increased Regulatory Scrutiny

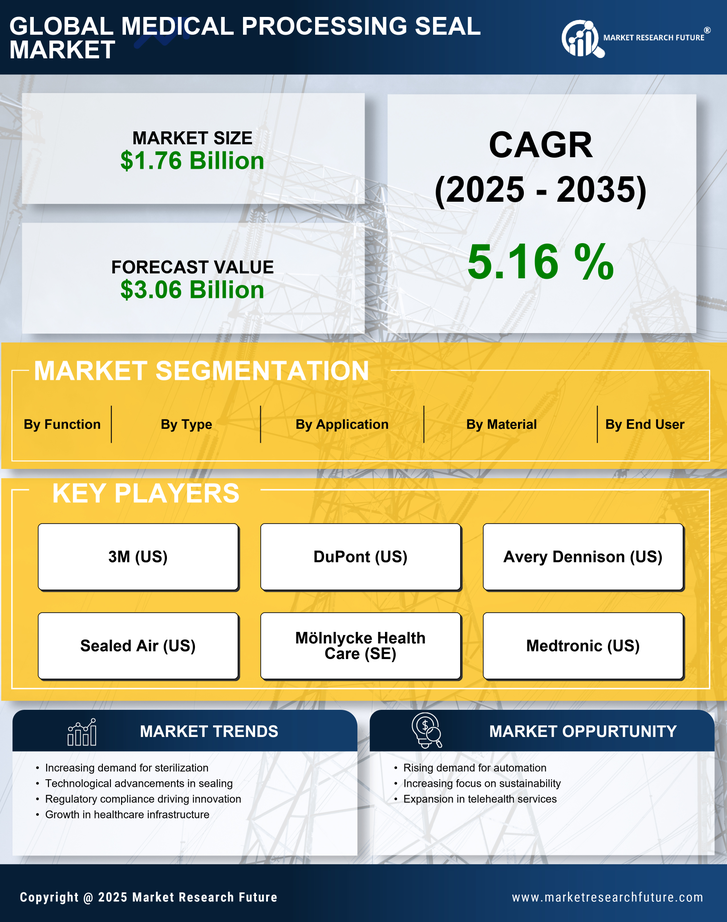

Increased regulatory scrutiny is a crucial factor impacting the Medical Processing Seal Market. Regulatory bodies are imposing stringent guidelines to ensure the safety and efficacy of medical products, which in turn drives the demand for reliable sealing solutions. Compliance with these regulations necessitates the use of high-quality seals that can withstand rigorous testing and validation processes. The market is witnessing a shift towards materials that not only meet regulatory standards but also offer enhanced performance characteristics. This trend is expected to contribute to a market growth rate of approximately 5% over the next few years, as manufacturers adapt to these evolving regulatory landscapes. Thus, the Medical Processing Seal Market is likely to see a surge in demand for innovative sealing technologies that comply with these stringent requirements.

Growing Focus on Patient Safety

The growing focus on patient safety is a pivotal driver of the Medical Processing Seal Market. Healthcare providers are increasingly prioritizing the implementation of measures that minimize the risk of contamination and ensure the safe delivery of medical products. This heightened awareness has led to a surge in demand for effective sealing solutions that guarantee the integrity of medical devices. Market Research Future suggests that the emphasis on patient safety is likely to propel the Medical Processing Seal Market, with an anticipated growth rate of around 6.5% in the coming years. As a result, manufacturers are compelled to innovate and enhance their sealing technologies to meet the stringent safety standards set forth by healthcare authorities.

Innovations in Packaging Technologies

Innovations in packaging technologies are significantly influencing the Medical Processing Seal Market. The advent of smart packaging solutions, which incorporate features such as temperature monitoring and tamper-evidence, is reshaping the landscape. These advancements not only enhance the safety and efficacy of medical products but also align with the growing consumer demand for transparency and traceability. Market analysts indicate that the packaging segment is expected to witness a growth rate of around 6% annually, driven by the need for improved shelf life and product integrity. As a result, companies are investing in research and development to create innovative sealing solutions that meet these evolving requirements, thereby fostering growth within the Medical Processing Seal Market.

Expansion of Healthcare Infrastructure

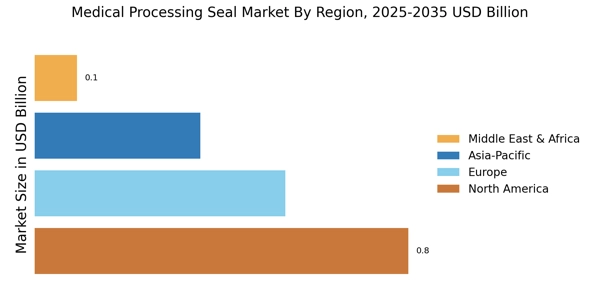

The expansion of healthcare infrastructure is a significant driver of the Medical Processing Seal Market. As countries invest in upgrading and expanding their healthcare facilities, the demand for medical devices and associated sealing solutions is expected to rise. This trend is particularly evident in emerging markets, where healthcare systems are rapidly evolving to meet the needs of growing populations. Analysts project that the healthcare infrastructure sector will experience a growth rate of approximately 8% annually, which will subsequently boost the demand for effective sealing technologies. Consequently, the Medical Processing Seal Market is poised for growth as manufacturers align their product offerings with the increasing requirements of modern healthcare facilities.

Rising Demand for Sterile Medical Devices

The increasing demand for sterile medical devices is a primary driver of the Medical Processing Seal Market. As healthcare facilities strive to enhance patient safety, the need for effective sealing solutions has surged. According to recent data, the market for sterile medical devices is projected to grow at a compound annual growth rate of approximately 7.5% over the next five years. This growth is largely attributed to the rising prevalence of chronic diseases and the expanding geriatric population, which necessitates the use of sterile products. Consequently, manufacturers are focusing on developing advanced sealing technologies that ensure the integrity and sterility of medical devices, thereby propelling the Medical Processing Seal Market forward.