Growing Automotive Industry

The Mechanical Tube Pipe Market is also benefiting from the growth of the automotive sector, which is increasingly utilizing mechanical tube pipes in various applications. With the automotive industry projected to expand at a compound annual growth rate of approximately 6%, the demand for lightweight and durable materials is on the rise. Mechanical tube pipes are essential for manufacturing components such as exhaust systems, chassis, and fuel lines. The trend towards electric vehicles is further influencing the market, as these vehicles require advanced piping solutions to optimize performance and efficiency. Consequently, manufacturers are likely to focus on developing innovative pipe designs that cater to the evolving needs of the automotive industry, thereby enhancing their market presence.

Rising Demand in Construction Sector

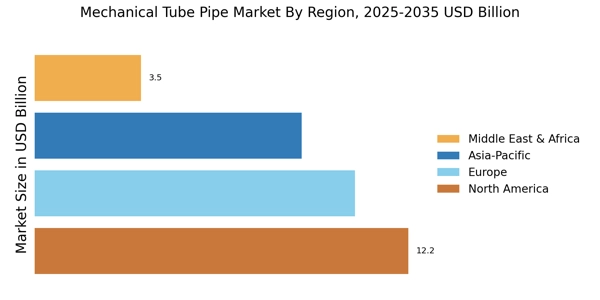

The Mechanical Tube Pipe Market is experiencing a notable surge in demand, primarily driven by the expanding construction sector. As urbanization accelerates, the need for robust infrastructure, including residential and commercial buildings, is increasing. In 2025, the construction industry is projected to grow at a rate of approximately 5.5% annually, which directly influences the consumption of mechanical tube pipes. These pipes are essential for various applications, including plumbing, HVAC systems, and structural support. The increasing focus on sustainable building practices further propels the demand for high-quality mechanical tube pipes, as they are often preferred for their durability and recyclability. Consequently, manufacturers are likely to invest in innovative production techniques to meet this rising demand, thereby enhancing their market position.

Increased Investment in Energy Sector

The Mechanical Tube Pipe Market is significantly influenced by the rising investments in the energy sector, particularly in oil and gas exploration and production. As energy demands continue to escalate, there is a corresponding need for efficient transportation and distribution systems, which rely heavily on mechanical tube pipes. In 2025, investments in the energy sector are expected to reach unprecedented levels, with a focus on enhancing infrastructure to support extraction and distribution processes. This trend is likely to drive the demand for high-performance mechanical tube pipes that can withstand extreme conditions. Additionally, the shift towards renewable energy sources, such as wind and solar, is creating new opportunities for the mechanical tube pipe market, as these systems require specialized piping solutions.

Technological Innovations in Manufacturing

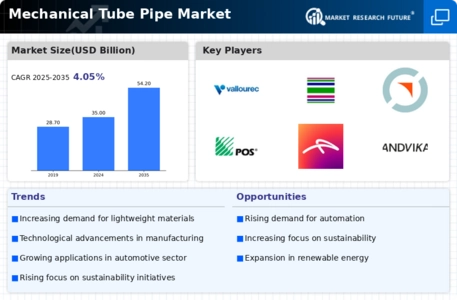

Technological advancements are playing a pivotal role in shaping the Mechanical Tube Pipe Market. Innovations in manufacturing processes, such as the adoption of automation and advanced welding techniques, are enhancing production efficiency and product quality. For instance, the implementation of computer numerical control (CNC) machines allows for precise cutting and shaping of pipes, which is crucial for meeting stringent industry standards. Furthermore, the integration of smart technologies in manufacturing is expected to streamline operations and reduce waste. As a result, companies that embrace these technological innovations are likely to gain a competitive edge in the market. The overall impact of these advancements is anticipated to contribute to a projected market growth rate of around 4.8% over the next few years.

Regulatory Support for Infrastructure Projects

Regulatory frameworks are increasingly supporting infrastructure projects, which is positively impacting the Mechanical Tube Pipe Market. Governments are recognizing the importance of modernizing infrastructure to promote economic growth and sustainability. In 2025, several countries are expected to implement policies that facilitate investment in infrastructure development, including transportation, water supply, and energy systems. This regulatory support is likely to create a favorable environment for the mechanical tube pipe market, as these pipes are integral to various infrastructure applications. Additionally, the emphasis on safety and quality standards is driving manufacturers to innovate and improve their product offerings. As a result, the mechanical tube pipe market is poised for growth, with an anticipated increase in demand driven by these supportive regulatory measures.