Rising Demand in Automotive Sector

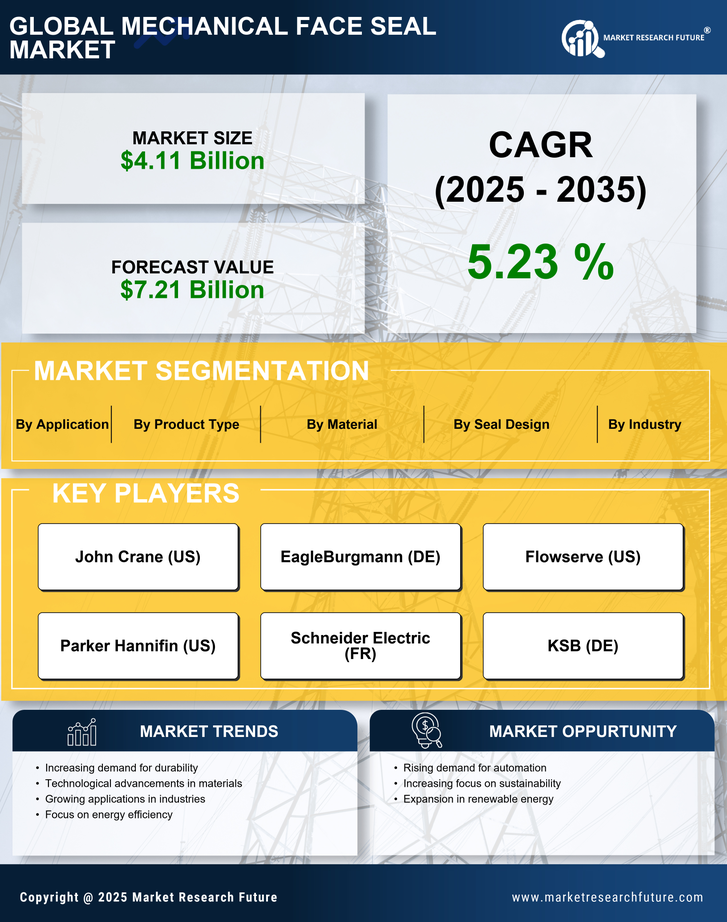

The Mechanical Face Seal Market is experiencing a notable surge in demand, particularly within the automotive sector. As manufacturers increasingly prioritize efficiency and reliability, the adoption of mechanical face seals in various automotive applications is becoming more prevalent. This trend is driven by the need for enhanced performance in engines and transmission systems, where mechanical face seals play a crucial role in preventing fluid leakage. According to recent data, the automotive segment is projected to account for a significant share of the market, with an estimated growth rate of around 5% annually. This growth is indicative of the broader trend towards advanced sealing solutions that can withstand the rigors of modern automotive engineering.

Regulatory Pressures and Compliance

The Mechanical Face Seal Market is also shaped by increasing regulatory pressures aimed at ensuring safety and environmental compliance. Governments and regulatory bodies are implementing stringent guidelines regarding emissions and leakage prevention, particularly in industries such as oil and gas and chemical manufacturing. These regulations necessitate the use of high-quality sealing solutions, including mechanical face seals, to meet compliance standards. As a result, manufacturers are compelled to invest in advanced sealing technologies that align with regulatory requirements. This trend is expected to drive market growth, with projections indicating a potential increase in demand for mechanical face seals by around 4% as industries adapt to these evolving regulations.

Expansion in Industrial Applications

The Mechanical Face Seal Market is witnessing substantial growth due to its expanding applications in various industrial sectors. Industries such as oil and gas, chemical processing, and manufacturing are increasingly utilizing mechanical face seals to enhance equipment reliability and reduce maintenance costs. The ability of these seals to operate effectively under extreme conditions, including high pressure and temperature, makes them indispensable in critical applications. Market data suggests that the industrial segment is expected to grow at a compound annual growth rate of approximately 6% over the next few years. This expansion reflects a broader trend towards optimizing operational efficiency and minimizing downtime in industrial processes.

Increased Focus on Energy Efficiency

The Mechanical Face Seal Market is increasingly influenced by a growing emphasis on energy efficiency across various sectors. As organizations strive to reduce operational costs and minimize environmental impact, the demand for sealing solutions that contribute to energy savings is rising. Mechanical face seals are recognized for their ability to prevent leaks, thereby enhancing the overall efficiency of machinery and systems. This focus on energy efficiency is expected to propel market growth, with estimates suggesting a potential increase in demand by approximately 5% over the next few years. Companies are likely to prioritize the adoption of mechanical face seals as part of their sustainability initiatives.

Technological Innovations in Seal Design

Technological advancements are significantly influencing the Mechanical Face Seal Market, leading to the development of innovative seal designs that offer improved performance and durability. Manufacturers are investing in research and development to create seals that can withstand harsher environments and provide better sealing capabilities. For instance, the introduction of advanced materials and coatings has enhanced the resistance of mechanical face seals to wear and corrosion. This trend is likely to drive market growth, as industries seek to adopt cutting-edge sealing solutions that can enhance the longevity and reliability of their equipment. The market is projected to see a growth rate of around 4% as these innovations gain traction.