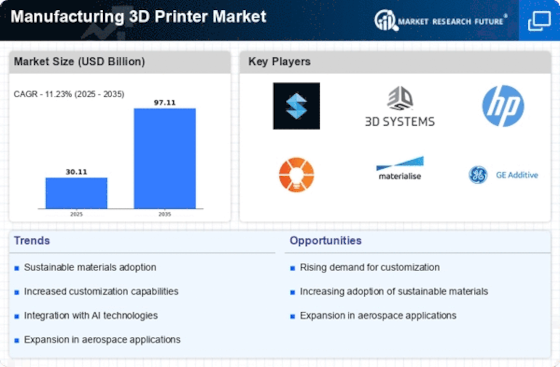

Cost Efficiency in Production

The Manufacturing 3D Printer Market is experiencing a notable shift towards cost efficiency in production processes. As companies seek to reduce operational costs, 3D printing technology offers a compelling solution by minimizing material waste and lowering labor expenses. According to recent data, the adoption of 3D printing can reduce production costs by up to 70% in certain applications. This cost-effectiveness is particularly appealing to small and medium-sized enterprises, which may lack the resources for traditional manufacturing methods. Furthermore, the ability to produce complex geometries without the need for expensive tooling contributes to the overall financial viability of 3D printing. As a result, more manufacturers are integrating 3D printing into their operations, driving growth in the Manufacturing 3D Printer Market.

Rapid Prototyping Capabilities

The Manufacturing 3D Printer Market is significantly influenced by the demand for rapid prototyping capabilities. Businesses across various sectors are increasingly recognizing the advantages of 3D printing in accelerating product development cycles. This technology allows for the quick creation of prototypes, enabling companies to test and iterate designs more efficiently. Recent statistics indicate that 70% of manufacturers report reduced time-to-market for new products due to 3D printing. The ability to swiftly produce prototypes not only enhances innovation but also allows for better alignment with consumer preferences. Consequently, the emphasis on rapid prototyping is propelling the growth of the Manufacturing 3D Printer Market, as organizations strive to remain competitive in fast-paced markets.

Advancements in Material Science

The Manufacturing 3D Printer Market is witnessing transformative advancements in material science, which are expanding the range of applications for 3D printing. Innovations in materials, such as high-performance polymers and metal alloys, are enabling manufacturers to produce parts that meet stringent industry standards. For instance, the introduction of biocompatible materials has opened new avenues in the medical sector, allowing for the production of customized implants and prosthetics. Additionally, the market for advanced materials is projected to grow at a compound annual growth rate of 25% over the next five years. This evolution in material capabilities is likely to enhance the versatility and appeal of 3D printing, further driving the Manufacturing 3D Printer Market.

Customization and On-Demand Production

The Manufacturing 3D Printer Market is increasingly driven by the demand for customization and on-demand production. Consumers are seeking personalized products tailored to their specific needs, and 3D printing offers a unique solution to this challenge. The technology enables manufacturers to produce small batches of customized items without incurring the high costs associated with traditional manufacturing. Recent data indicates that the market for customized 3D printed products is expected to reach 10 billion dollars by 2027. This shift towards on-demand production not only enhances customer satisfaction but also reduces inventory costs for manufacturers. As a result, the emphasis on customization is likely to propel the growth of the Manufacturing 3D Printer Market.

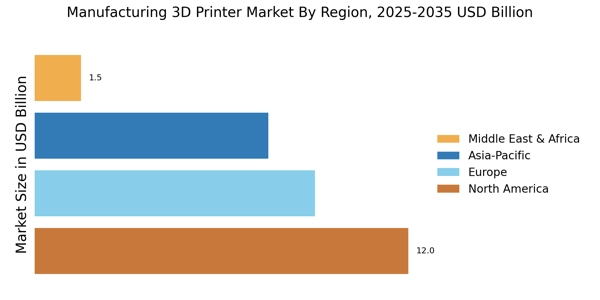

Increased Adoption in Aerospace and Automotive Sectors

The Manufacturing 3D Printer Market is experiencing increased adoption within the aerospace and automotive sectors, where the demand for lightweight and complex components is paramount. 3D printing technology allows manufacturers to create intricate designs that traditional methods cannot achieve, leading to weight reductions and improved fuel efficiency. Recent reports suggest that the aerospace industry alone is expected to invest over 3 billion dollars in additive manufacturing technologies by 2026. This trend is indicative of a broader shift towards innovative manufacturing solutions that enhance performance and sustainability. As these industries continue to embrace 3D printing, the Manufacturing 3D Printer Market is poised for substantial growth.