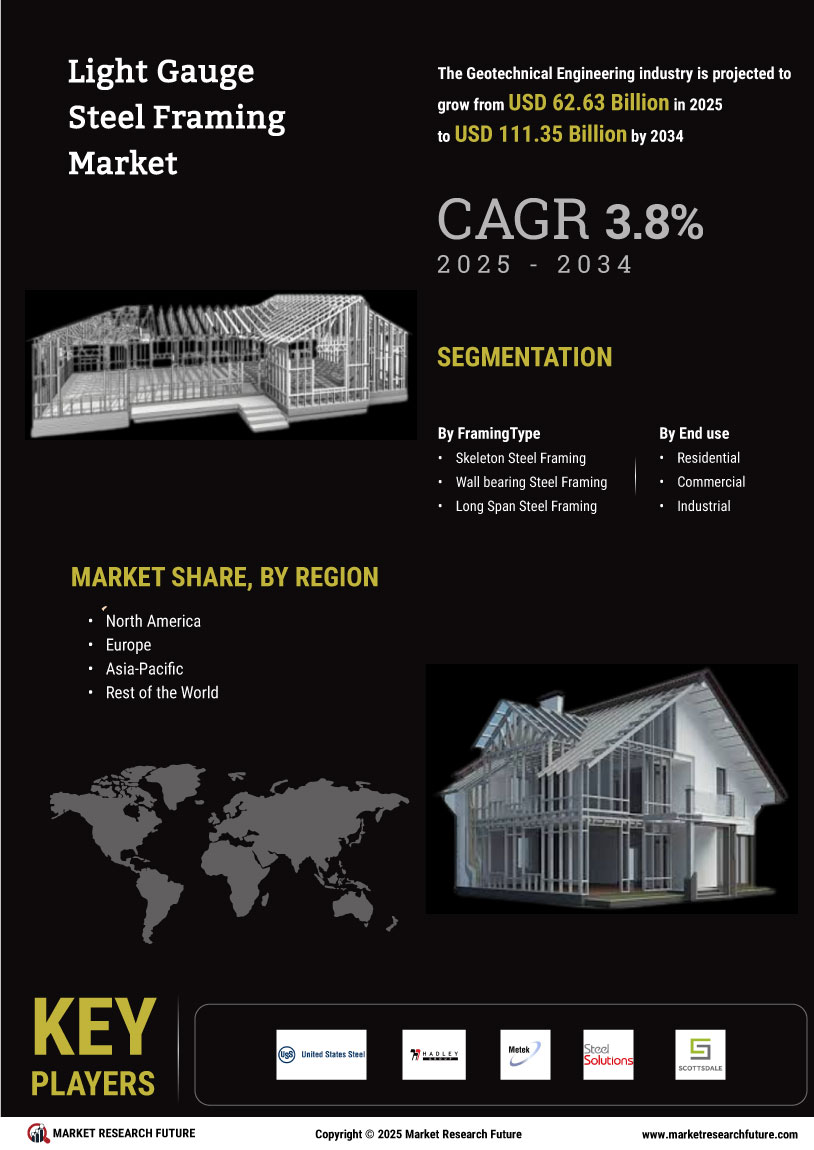

Light Gauge Steel Framing Market Summary

As per MRFR analysis, the Light Gauge Steel Framing Market was estimated at 38.4 USD Billion in 2024. The Light Gauge Steel Framing industry is projected to grow from 40.4 USD Billion in 2025 to 67.8 USD Billion by 2035, exhibiting a compound annual growth rate (CAGR) of 5.3% during the forecast period 2025 - 2035.

Key Market Trends & Highlights

The Light Gauge Steel Framing Market is poised for substantial growth driven by sustainability and technological advancements.

- The market is increasingly influenced by sustainability initiatives, reflecting a broader trend towards eco-friendly construction practices.

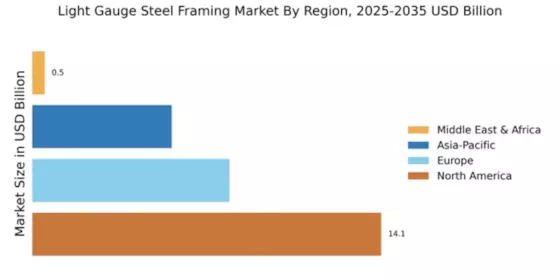

- North America remains the largest market, while the Asia-Pacific region is recognized as the fastest-growing area for light gauge steel framing.

- Residential construction continues to dominate the market, whereas commercial construction is emerging as the fastest-growing segment.

- Key market drivers include urbanization trends and regulatory support for sustainable building practices.

Market Size & Forecast

| 2024 Market Size | 38.4 (USD Billion) |

| 2035 Market Size | 67.8 (USD Billion) |

| CAGR (2025 - 2035) | 5.3% |

Major Players

BlueScope Steel (AU), Nucor Corporation (US), ClarkDietrich Building Systems (US), Tata BlueScope Steel (JV) (India), ArcelorMittal (LU), Metsec Plc (Voestalpine) (UK), FRAMECAD Ltd. (NZ), Hadley Group (UK), SCAFCO Steel Stud Company (US), Steel Frame Solutions (US)