Research Methodology on High Strength Steel Market

Introduction

Research Methodology is a systematic process used for the analysis of data to arrive at accurate results. Methodology involves systematic planning and the application of methods and techniques to answer questions and issues related to market research. It is an approach, specifically designed for a given research purpose, to obtain meaningful and valid results. This research report on the “High-Strength Steel Market” includes both primary and secondary research. Primary research provides the information obtained from interviews, surveys, primary sources and various market experts while secondary research extracts information from published sources.

Scope of the Study

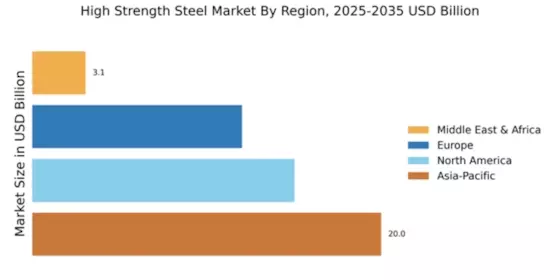

The report also covers the historical data of the market since 2018 and provides the market forecast from 2023-2030. The product types covered, include automotive steel, construction steel, oil & gas steel, and others. The market segmentation by end users includes automotive, construction, oil & gas, and others. Further, the market is majorly segmented by regions including North America, Europe, Asia-Pacific, and the Middle East & Africa.

Research Objectives

The primary goal of the research is to analyze and estimate the global High-Strength Steel market size over the forecast period 2023-2030.

• Evaluate and forecast market size and market share by product & application

• Analyze the drivers and trends influencing the growth of the market

• Assess the impact of key factors on the market dynamics

• Analyze regional market size, share, and volume

• Identify key companies and competitive strategies adopted by them

• Establish current industry trends for the global High-Strength Steel market

Research Strategy

The research and analysis of the global High-Strength Steel Market is an extensive and systematic process followed by a set of guidelines that help in obtaining data from multiple sources to get an accurate picture of the market. The following research strategy was used to obtain the data needed for this report:

Secondary Research:

Secondary research is the first stage of the study in which market intelligence is acquired from internal and external sources. The market view is based on secondary research such as company websites, press releases, annual reports, investor presentations, financial reports, white papers, market databases, articles, government sources, and other related sources.

Primary Research:

Primary research included an interview with industry pros, such as CEOs, VPs, directors, and marketing executives. The primary interviewing with market experts was used to validate the data obtained through secondary research. The interviewers conducted a one-on-one interview session with the key market external and internal subject matter experts.

Bottom-up Approach:

The bottom-up approach is used for market estimation by using bottom-up modelling. Primary interviews are conducted with major industry experts to estimate and understand the data collected from secondary research such as market size, share and forecast. Bottom-up approach is also used to validate the estimated market size and market share of the global High-Strength Steel Market.

Top-Down Approach:

The top-down approach is used to validate the market size and market share of the global High-Strength Steel Market. The approach is used to define the global market size of the High-Strength Steel Market. The total market size is estimated first based on the bottom-up approach by assessing the size of the regional markets. This approach is used by analyzing the data points collected from the primary researchers from the industry.

Factor Analysis:

The factor analysis approach was used to analyze and determine the factors that are influencing the market size and market growth of the global High-Strength Steel Market. The study has also considered macro-economic factors such as GDP, population growth, disposable income, industry growth, price trends, capacity utilization, and cost of production that are impacting the growth of the global High-Strength Steel Market.

Time-Series Analysis:

Time-series analysis was used to analyze the current and historical market trends in the global High-Strength Steel Market. This analysis is conducted to determine the market evolution and growth over some time.

Demand Side and Supply Side Data Triangulation

Data triangulation is used to analyze the availability of data from the demand side and supply side. The demand side is analyzed by considering parameters such as production, market size, market share, distribution channels, and revenue generated by the market. The supply side is analyzed by considering parameters such as production capacity, import and export volume, price trends, and cost.

Stakeholder’s Analysis:

The stakeholder analysis is conducted by including the stakeholders such as investors, shareholders, suppliers, key vendors, dealers, distributors, and other stakeholders for the global High-Strength Steel Market. This analysis determines the effect of the various stakeholders on the market growth and their influence on the global High-Strength Steel Market.

Conclusion

The above-mentioned research methodology systemically explains the process used to obtain relevant data for a systematic assessment of the global High-Strength Steel Market. The methodology employed in this study includes primary and secondary research, bottom-up and top-down approaches, analysis, factor analysis, time-series analysis, and demand-side and supply-side data triangulation. This research process results in an accurate and established market size, accurate market share and market forecast for 2023 to 2030.