Leading Edge Protection for Wind Turbine Blades Market Summary

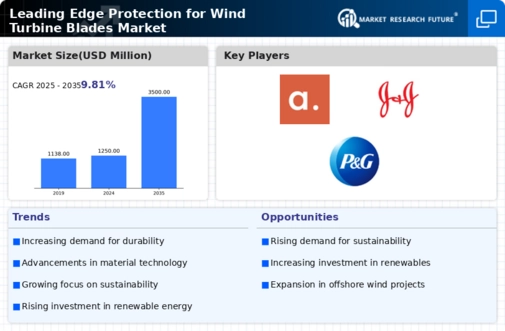

As per MRFR analysis, the Leading Edge Protection Market for Wind Turbine Blades Size was valued at USD 3,24,279 million in 2024. The Leading-Edge Protection Market for Wind Turbine Blades Industry is projected to grow from USD 3,51,701.4 million in 2025 to USD 7,11,734.7 million by 2035, exhibiting a compound annual growth rate (CAGR) of 7.3% during the forecast period (2025 - 2035).

Key Market Trends & Highlights

The Leading-edge protection (LEP) for wind turbine blades is experiencing transformative trends driven by the global push for renewable energy efficiency and durability.

- Advanced coatings dominate LEP evolution, with polyurethane and epoxy formulations leading due to superior abrasion resistance and flexibility.

- Nanocomposite tapes and hybrid shells provide retrofit durability, outperforming traditional paints by withstanding 10x more impact cycles in lab tests. Trends show a shift toward UV-curable applications for faster field deployment, cutting downtime by 50% during maintenance.

- Integration of IoT sensors and AI-driven monitoring is revolutionizing LEP, enabling condition-based recoating over scheduled overhauls. Drones with hyperspectral imaging detect erosion at 0.1mm precision, paired with predictive analytics to forecast failures weeks ahead.

- OEM-coating firm partnerships accelerate customized solutions; e.g., Arctura-Mankiewicz's ArcGuide lightning-LEP hybrid. Supply chain localization in India and Brazil counters raw material volatility.

Market Size & Forecast

| 2024 Market Size | 3,24,279 (USD Million) |

| 2035 Market Size | 7,11,734.7 (USD Million) |

| CAGR (2025 - 2035) | 7.3% |

Major Players

INDRAERO, Spirit AeroSystems, Inc., GKN plc, FACC AG, RUAG International Holding AG, Kawasaki Heavy Industries Ltd., Latécoère, Triumph Group Inc, Korea Aerospace Industries Ltd, Terma A/S, Aernnova, Kaman Corporation, Collins Aerospace, Primus Aerospace, And Others

Europe leads the global leading-edge protection (LEP) market for wind turbine blades, fueled by aggressive offshore wind targets and stringent durability regulations. The region commands the second-largest share in wind turbine protection. Offshore dominance in the North Sea, where harsh salt spray and storms demand rain-erosion coatings. EU Green Deal mandates for recyclable, low-VOC materials, boosting bio-based LEP. Digital twins and drone inspections optimize LEP maintenance, cutting costs in high-wind zones. Focus on 20+ year blade lifespans drives hybrid tapes and films.

Europe leads the global leading-edge protection (LEP) market for wind turbine blades, fueled by aggressive offshore wind targets and stringent durability regulations. The region commands the second-largest share in wind turbine protection. Offshore dominance in the North Sea, where harsh salt spray and storms demand rain-erosion coatings. EU Green Deal mandates for recyclable, low-VOC materials, boosting bio-based LEP. Digital twins and drone inspections optimize LEP maintenance, cutting costs in high-wind zones. Focus on 20+ year blade lifespans drives hybrid tapes and films.