Technological Innovations

Technological advancements play a crucial role in shaping the Lathe Machines Market. The introduction of computer numerical control (CNC) technology has revolutionized lathe operations, allowing for greater precision and efficiency. CNC lathes are increasingly favored for their ability to produce complex geometries with minimal human oversight. The market for CNC lathe machines is projected to grow significantly, with estimates suggesting a CAGR of around 6% over the next few years. Additionally, innovations such as multi-axis lathes and hybrid machines that combine additive and subtractive manufacturing processes are gaining traction. These advancements not only enhance the capabilities of lathe machines but also cater to the evolving needs of various industries. As manufacturers seek to optimize their production processes, the emphasis on technological innovations will likely continue to drive the Lathe Machines Market.

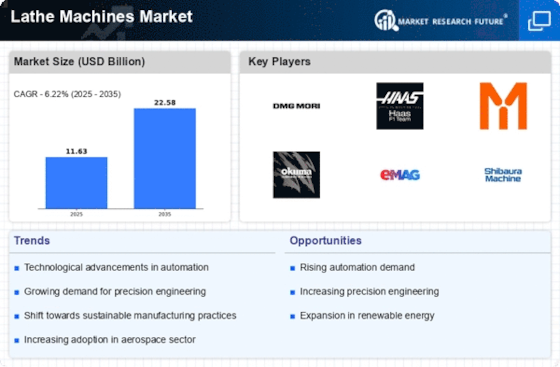

Rising Demand in Manufacturing Sector

The Lathe Machines Market is experiencing a notable surge in demand, primarily driven by the expansion of the manufacturing sector. As industries such as automotive, aerospace, and electronics continue to grow, the need for precision machining tools, including lathe machines, becomes increasingly critical. In recent years, the manufacturing sector has shown a compound annual growth rate (CAGR) of approximately 4.5%, indicating a robust market environment. This growth is likely to propel the Lathe Machines Market forward, as manufacturers seek advanced machinery to enhance productivity and efficiency. Furthermore, the trend towards automation in manufacturing processes necessitates the adoption of sophisticated lathe machines, which can operate with higher precision and lower human intervention. Consequently, the rising demand in the manufacturing sector is a pivotal driver for the Lathe Machines Market.

Increased Investment in Infrastructure

Investment in infrastructure development is another significant driver for the Lathe Machines Market. Governments and private entities are allocating substantial resources towards building and upgrading infrastructure, including transportation, energy, and industrial facilities. This trend is expected to create a heightened demand for precision-engineered components, which in turn necessitates the use of advanced lathe machines. For instance, the construction of new transportation networks and energy projects requires high-quality machined parts that can withstand rigorous operational conditions. As infrastructure projects continue to proliferate, the Lathe Machines Market is likely to benefit from increased orders for lathe machines capable of producing these essential components. The ongoing investment in infrastructure is thus a vital factor propelling the growth of the Lathe Machines Market.

Growth in Aerospace and Defense Sectors

The aerospace and defense sectors are emerging as significant contributors to the Lathe Machines Market. With the increasing demand for advanced aircraft and defense equipment, manufacturers are investing heavily in precision machining technologies. The aerospace industry alone is projected to reach a market value of over 800 billion USD by 2027, which is likely to stimulate the demand for high-quality lathe machines. These machines are essential for producing critical components such as turbine blades, landing gear, and structural parts. Furthermore, the defense sector's focus on modernization and technological upgrades is expected to further bolster the Lathe Machines Market. As these sectors continue to expand, the need for reliable and efficient lathe machines will remain a driving force in the market.

Customization and Versatility Requirements

The need for customization and versatility in manufacturing processes is increasingly influencing the Lathe Machines Market. As industries strive to meet specific customer requirements, the demand for lathe machines that can be easily adapted to various applications is on the rise. Manufacturers are seeking machines that offer flexibility in terms of tooling and programming, allowing for quick changes in production runs. This trend is particularly evident in sectors such as automotive and consumer goods, where product differentiation is key. The ability to produce small batches of customized parts efficiently is becoming a competitive advantage. Consequently, lathe machine manufacturers are focusing on developing versatile machines that can accommodate diverse machining tasks, thereby driving growth in the Lathe Machines Market.